Cavities & 3D moulds

Your micro metal components precisely lasered instead of milled

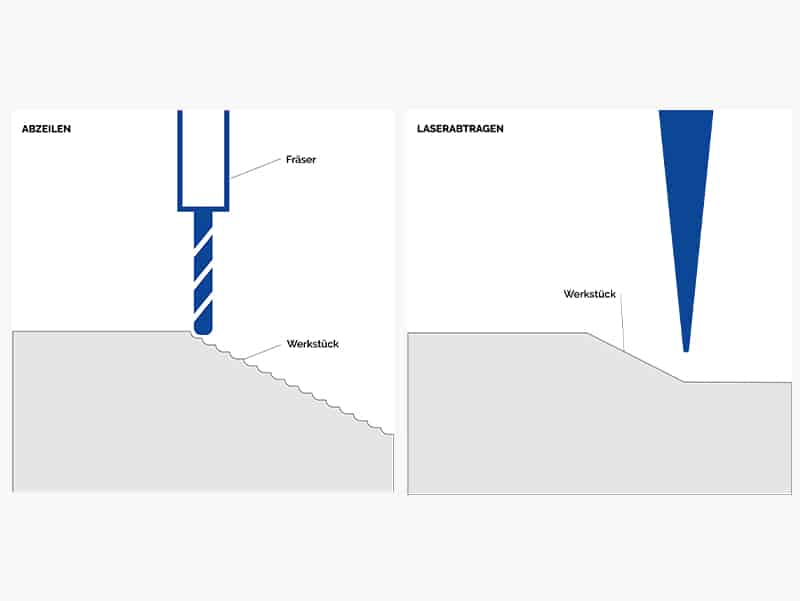

Do you already have lasers - or are you still milling?

We manufacture your cavities and topologies with 100% reproducibility on a contract basis. Compared to HSC milling, laser ablation scores in several ways: with smooth radius transitions, excellent surface qualities, lower tolerances and longer tool life. When can you request your free sample part?

Your added value with HAILTEC

Advantages for your cavities

Your high-tech partner for 3-D mold and cavity

Why choose HAILTEC as your supplier?

Expert for cavities made of hard materials

Tungsten carbide or powder metallurgically produced high-performance steels such as > 67HRC are difficult to machine with milling technology. But ultrashort pulse laser technology also scores points with aluminum or stainless steel. The precise and material-friendly machining process surpasses high-speed cutting (HSC milling) in terms of precision:

- Increased service life of the molds

- Process reliability

- Reproducibility

- No electrode manufacturing necessary (≠ die-sinking EDM)

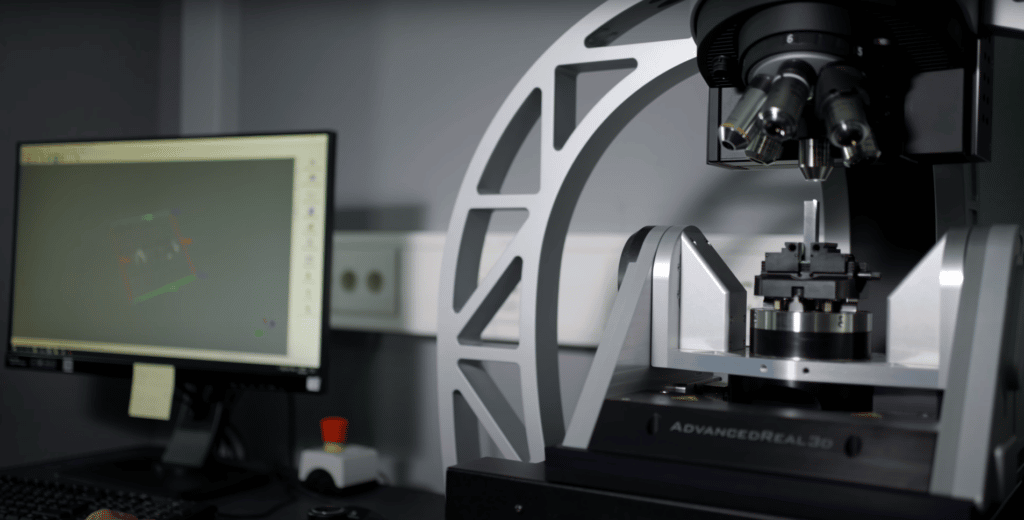

Measurement during production

For micrometer-precise tool shapes

On water-cooled precision systems from DMG MORI, we also manufacture larger tool shapes of up to 250 mm x 250 mm for you. The laser creates the finished cavity or topology directly from the 3D model, in just one clamping and without any machining forces acting on it. Thanks to repeatable process parameters, one mold is exactly like another. This is also ensured by the measurement during production: The Alicona µCMM measuring system measures the mold with µm precision.

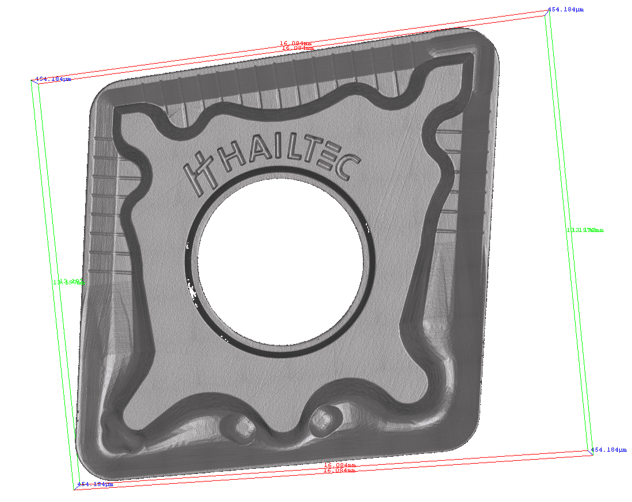

Product examples cavity production

Topology

We manufacture the smallest molds and cavities for you quickly and with high precision. The picture shows the topology for an indexable insert.

The & Mold die casting mold

3D die casting mold made of tool steel, laser machined

3D molds and embossing tools

Without heat-affected zone, we laser your molds or punches with high precision, even in carbide and hardened PM steels:

- Tolerances in the µm range

- Surface finish up to Ra 0.1 µm

These added values await you at HAILTEC

Good reasons for laser-microcut components

Precision

Micrometre-fine ridges, smallest spot diameters and cuts that are repeatable and true to geometry - these are enormous advantages of laser micro cutting.

For maximum precision, we combine the cold femtosecond laser with cutting gas - and thus achieve the finest ridges and burr-free, almost right-angled cut edges with surface qualities down to Ra 0.2 µm.

The quality of your micro components are measured and monitored by optical measuring system with an accuracy of +/-1µm

Economic efficiency

As a contract manufacturer for laser micromachining, we cut your parts with µm-accurate fits and post-processing-free edges. This is made possible by special ultra-short pulse laser technology.

The laser cut produced with this method is comparable in quality to wire erosion. The advantage of UKP laser microcutting: the laser is significantly more economical than wire erosion, and that from batch size 1.

Material diversity

Since the ultrashort pulse laser cuts without thermal influence, you get high-quality and reproducible results - regardless of the material.

Brittle-hard and temperature-sensitive materials as well as composites can also be easily processed with laser micro cutting. We can cut nitinol, titanium, medical stainless steels and copper for you.

Your job shop for cavities & 3D moulds

You need filigree 3D molds in blanks or components? With a unique high-tech park and years of experience, we manufacture your molds and cavities. By the way: In design, the ultrashort pulse laser opens up immense design and material freedom for you.

- fast

- economic

- in outstanding quality