Inscriptions & Engravings

Which components may we mark for you?

Filigree inscriptions independent of the material

Whether glass, ceramics, plastics or carbide: engraving and marking fragile or temperature-sensitive materials is a challenge for conventional technologies. That's why we rely on the latest laser technology and "cold" processing. Take advantage of this technological lead and commission us as your supplier.

Take advantage of the benefits of ultra-short pulse laser technology for your marking and engraving needs.

Permanently legible markings regardless of the material

Advantages of engraving and black marking

| Advantages |

|---|

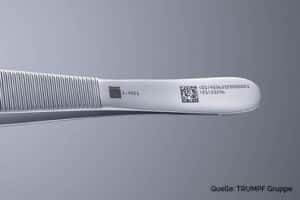

| Black Marking: Corrosion resistant, viewing angle independent, ideal also for UDI markings |

| No heat input into the material and thus no damage or structural change |

| Huge freedom of design and materials |

Engraving, lettering or black marking

Application examples for micro components

Please insert pictures here, e.g. of the QR code in plastic, hand holding the filigree "HAILTEC" plate

- Three-dimensional shape engravings on free-form surfaces

- 3D laser engraving / laser engraving

- Functional microstructures and microcomponents

- Replacement or repair of moulds and tools in the micro range

- UDI codes

- Serial numbers

- Data Matrix Codes

- Finest graphics

Why HAILTEC should be your partner

Your Jobshop for Engraving & Black Marking

Do you need precise molds for complex tools? Do you want to mark components permanently? On high-tech laser systems and with years of experience in laser technology, we manufacture your filigree shapes as desired. And this is independent of the material. Because where conventional technologies reach their limits, the ultrashort pulse laser opens up unimagined design and material freedom. For example, with temperature-sensitive or ultra-hard materials such as hard metal or ceramics.

Frequently asked questions about ultra-short pulse laser technology

For which products is black marking with the UKP laser suitable?

UDI marking

- non-corrosive

- high contrast

- viewing angle stable

The UKP laser is ideally suited for marking the UDI (Unique Device Identification) according to the EU Medical Device Regulation (MDR).