Where high technology meets trust

For us, the best way into the future is through new technologies and human interaction. That is why we have been investing in employees, high-tech and expertise since 2004. For clients, we are not only a supplier of precise metal components, but also an ultra-fast and uncompromisingly reliable partner. We have four cutting technologies in-house: laser micro cutting, laser fine cutting, micro water jet cutting and punching technology.

One request, one audit, one contact

Agile and accurate to the µm, we work in a team with currently 30 people for you and with you. We have a background in prototype construction and work enthusiastically - even around the clock - until everything is just right. We crack seemingly unsolvable tasks with technological flair and the claim to make everything possible for you. Thanks to end-to-end digital processes, we stay on top of things even under time pressure.

Green technology, green heart

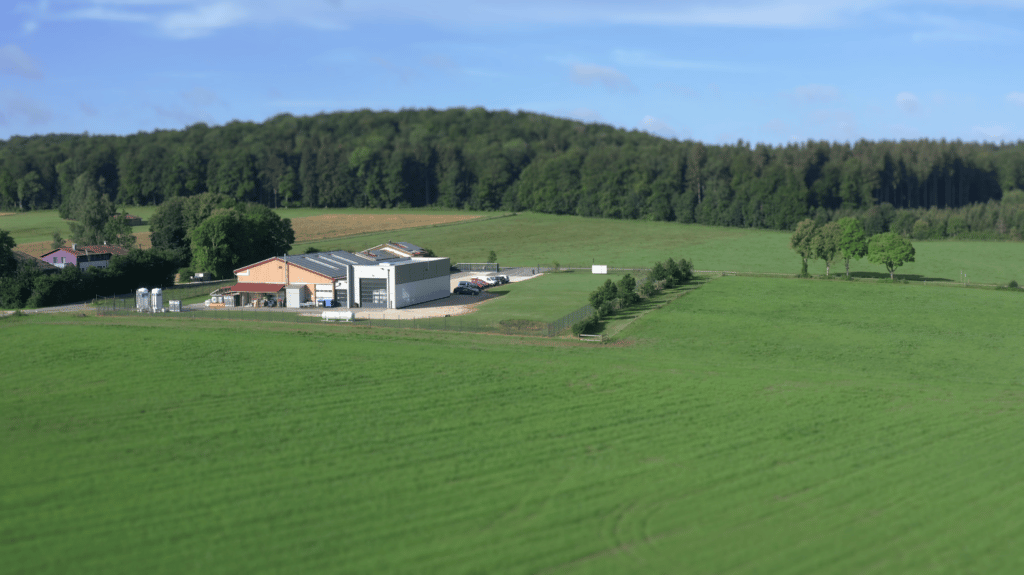

In front of the factory halls, the Alb buffaloes graze; inside, hearts beat for forward-looking technologies: Nature and technology have always belonged together for us. That's why we not only produce close to nature in the Swabian Alb, but also do so as CO2-neutrally as possible. For example, by using only green energy and generating most of it ourselves.

Get to know us - as a long-term partner who makes just about anything possible for you.

We have specialized in 3 service areas for you:

Your high-tech partner in the Swabian Alb natural landscape

History of HAILTEC

1998: Like many entrepreneurs, Wilfried Hailfinger starts out in a garage. But a metalworking business needs space. In 2004, he persuades his father to allow him to use the family farm. So Wilfried took over his parents' farm after all - albeit in a different way than expected. His father, a farmer who works with large machines, is skeptical at first: "You want to earn money with such tiny little metal parts?".

Soon there are bending presses in the former chicken house and the cowshed becomes a high-tech laser manufacturing facility. The inventive founder taps into new technologies and makes a name for himself in the industry. If you are stuck with a sample part or need a brilliant idea, HAILTEC is the right place to go. Even father Hailfinger is soon convinced of the great success of the small parts.

When Wilfried Hailfinger died completely unexpectedly in 2016, he left a painful gap. But fortunately, he is always generous with his knowledge and had brought soul-mate technicians to his side over the years. So now his "right hand man", Alexander Renz, is taking over the management overnight. Following the motto "flat hierarchies and steep technologies", Alex, together with a strong team, continues to develop the company in the spirit of the founder.

From farm to high technology

1998

Like many entrepreneurs, the talented inventor Wilfried Hailfinger started out in a garage

2004

Things really get going

In 2004, Wilfried Hailfinger established the company in his parents' former farmhouse. He creates the name HAILTEC from "Hailfinger" and "Technologie". He employs two people.

2005

Laser fine cutting

In 2005, HAILTEC invests in the first laser fineblanking machine. Laser technology is soon followed by other technologies.

2007

Own toolmaking

In 2007 HAILTEC establishes its own tool shop including design department in order to implement prototypes and small series even faster.

2015

HAILTEC grows

In 2015, 15 employees are already taking care of stamping and bending technology, laser processing, tool and fixture construction.

2016

Change in the management

2016 In January, Wilfried Hailfinger passes away unexpectedly. Alexander Renz, authorized signatory and plant manager, takes over the management and, together with the workforce, continues the life's work of the founder.

2017

Micro water jet cutting

2017 with the new micro waterjet cutting process, HAILTEC separates sensitive materials without the use of heat.

2018

Ultra-short pulse laser

2018 in August HAILTEC orders the first high-precision femtolaser system and lays the foundation for Germany's unique ultra-short pulse laser job store for embossing stamp production. In October, the developers of this laser source receive the Nobel Prize.

2019

15th anniversary

In 2019, HAILTEC celebrates its 15th company birthday and inaugurates the newly built factory hall at the site.

2020

DIN EN ISO 13485

2020 HAILTEC is a certified supplier for medical technology according to DIN EN ISO 13485:2016.

2021

DIN EN ISO 14001

2021 HAILTEC introduces its own environmental management system according to DIN EN ISO 14001.

2023

Groundbreaking ceremony

The excavator has started: the new building will soon offer approx. 1,000 m² more production space and around 700 m² for offices and social rooms.

2024

We grow with Aussafer

HAILTEC becomes a member of the Aussafer Group and thus embarks on an international growth course