UKP Black Marking

Your components marked in black

Durable, deep black, corrosion resistant

Using ultra-short pulse technology, we mark your components in deep black and with viewing angle stability with corrosion-resistant markings of any kind. The markings are still easily legible even after countless cleaning and passivation cycles.

Trust the laser experts

Advantages Black Marking

With black marking, the blackening does not result from annealing via an oxide layer, but rather as an optical effect due to the microstructure created in the material.

Your high-tech partner for black marking

Black marking is ideal for:

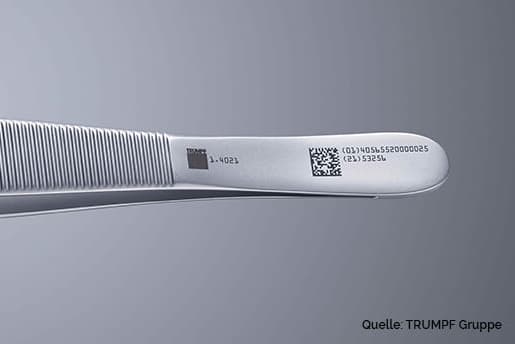

UDI marking

The UKP laser is ideally suited for marking the UDI (Unique Device Identification) according to the EU Medical Device Regulation (MDR).

- non-corrosive

- high contrast

- viewing angle stable

Your job store for Black Marking

- fast

- economic

- in outstanding quality

These added values await you at HAILTEC

Good reasons for ultrashort pulse laser components

permanently legible markings

No heat input into the material

jet black, stainless steel lettering

Member of networks and associations

HAILTEC - Your certified partner

Frequently asked questions about Black Marking

What added value does ultrashort-pulse laser technology bring to black marking?

- Permanently legible markings

- Deep black, corrosion resistant lettering

- No heat input into the material

How does Black Marking work?

What many do not know: The blackening in laser marking is not caused by tempering with an oxide layer. Rather, it is based on an optical effect caused by the microstructure generated in the material.

Which products does HAILTEC mark with the UKP laser?

Typical application examples include:

- Labeling with standard-compliant UDI data matrix;

- Labeling and marking with logo, serial number, graphics, barcode, characters, QR code, data matrix code, consecutive serial number etc.