Chipbreakers & Topologies

Your chipbreakers manufactured with ultra-short laser pulses

Spanbrecher: This is why outsourcing pays off

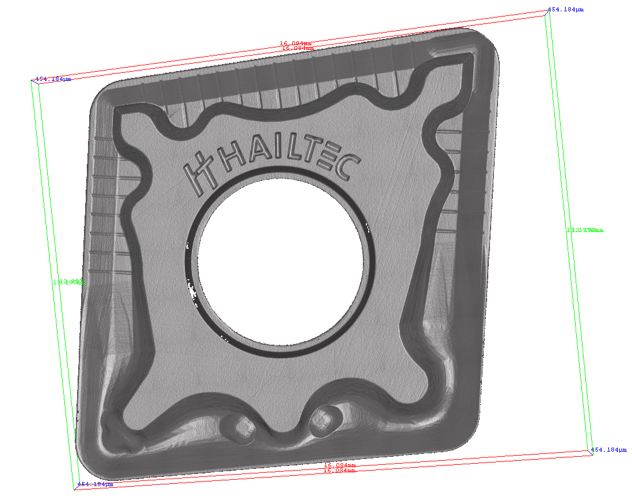

Save time, money and benefit from the latest technology: With chipbreakers from HAILTEC. We manufacture chipbreakers with surface qualities of up to Ra 0.1 µm without heat-affected zones (HAZ) for you on a contract basis:

With ultrashort pulse laser processing, chipbreakers can be inserted in 3D quickly and with µm precision, which pays off in prototyping and series production. On state-of-the-art laser systems with optical component recognition and tactile measuring probes, we precisely insert your chipbreaker geometry - for micro-precise chipbreakers with maximum surface quality.

Longer tool life, optimum chip control: When do you rely on HAILTEC for chipbreakers?

Chip breaker without HAILTEC

Rough and coarse surface finishes

Chip breaker from HAILTEC

Surface finishes up to Ra 0.1µm

Best roughness thanks to ultrashort pulse laser

High investment

Description what is the disadvantage

Latest laser technology

Benefit from the very latest technologies without investing in machines and people yourself

Disadvantage / XY

Description what is the disadvantage

From prototype to series

Describe what the advantage is

Disadvantage / XY

Description what is the disadvantage

Automated laser system for high throughput

Describe what the advantage is

Disadvantage / XY

Description what is the disadvantage

State-of-the-art measurement technology with userem Alicona µcmm

Describe what the advantage is

Chip breaker conventionally manufactured

Higher surface roughness

Visually, haptically and functionally rougher surfaces, surface damage e.g. due to microcracks and slag

Chip breaker UKP-lasered

Surface finishes up to Ra 0.1 µm

Significantly smoother surfaces and the elimination of a heat-affected zone have a positive effect on the service life of your tools

Lose connection

With mechanical processes or conventional laser technology, they are technologically limited, there is a risk of being overtaken by market competitors

Remain competitive

Benefit from the geometry freedom of the UKP laser and always use the latest technology plus expertise without having to invest in personnel and equipment yourself

Acceptable precision

Lack of geometry freedom and high process forces: Conventional processes do not achieve the precision of the ultrashort pulse laser, especially in carbide and high-hardness materials such as PCD / MIKD

Maximum precision

µm-accurate setup, auto-video setup and tactile probes ensure reliable positioning of chipbreaker geometries on your cutting tool with UKP technology

Lack of reproducibility

The lack of networked processes and automated measurement technology often means that parts cannot be reproduced exactly. Thermal influences of conventional laser technology also impair repeatable production

100% reproducible manufacturing

Thanks to digital, stable processes and the connected µCMM coordinate measuring machine from Alicona, the UKP laser manufactures your chipbreakers with repeatable accuracy

Your added value with HAILTEC

Plus points for your chipbreakers and chip grooves

Why choose HAILTEC as your supplier

Chipbreaker for your economical tool production

Long chips are often a nuisance, they make removal difficult and can hinder the machining process. With the help of precisely adapted chipbreakers, you can avoid these difficulties and increase the efficiency of your tool production. Technologically, we have been supporting cutting tool manufacturers for many years in the development and precision manufacture of micrometer-precise molds and topologies. As a subcontractor, we take over the complete machining for you, including clearance angles and chip grooves. Thanks to flexible automation, we can also manufacture series for you in a highly productive manner.

Comparison with conventional methods

Ultra-short laser pulses for high-hardness cutting materials

When machining diamond cutting materials, conventional mechanical processes (grinding, eroding) and even classic laser machining reach their limits. The causes include high process forces and thermal reactions. With ultrashort pulse laser technology, on the other hand, we can machine a wide range of materials for you: from soft materials to hard metals and tool steels to high-hardness materials such as monocrystalline diamond (MKD) or polycrystalline diamond (PCD).

The precise machining process has a beneficial effect on your chipbreakers.

Excellent chip control

Extended service life of your tools

Smooth surface finishes

Definable chip breaking

Minimal burr formation

Flexible range of applications

Your chipbreaker manufactured to nanometer precision

Measurement: during production and automated

Using ultra-short pulse laser technology, we create active chipbreakers and chip grooves for you directly from the 3D model. Measurements during production with Alicona µCMM ensure exact dimensional accuracy and reproducible results. Within the scope of quality assurance, we measure your parts in our laboratory with nanoscale measurement technology from Alicona and provide you with a measurement report upon request.

Product examples Chipbreaker / Chipbreaker

We manufacture the smallest chip grooves for your micro tools with expertise and femtocurrent laser beams of the ultrashort pulse laser. Some examples:

Chip groove

Carbide insert with PCD (polycrystalline diamond) insert

- no HAZ (Heat Affected Zone)

- Position tolerance blank/laser contour +/- 0.005 mm thanks to high-resolution CCD camera and tactile probe for blank alignment

- Surface roughness Ra 0.102 µm

Chipbreaker topology

Microgeometry manufactured with UKP laser:

- Chip breaker 3D shape from PCD

- µm-precise positioning of the chipbreaker geometry

- Long service life due to gentle machining

Pressing punch / insert made of carbide

Topology in carbide

- µm- accurate insertion of the topology

- No Heat Affected Zone

- accurate to size with measurement protocol

How to score with ultra-short pulse laser technology from HAILTEC

Plus points for your embossing and die cutting technology

More speed and quality

Thanks to "cold" laser processing, we manufacture your embossing dies particularly quickly and precisely: On precision machines from DMG MORI and TRUMPF with Tolerances of +/- 0.005 mm.

Molds directly from 3D model

Your molds, dies, bending punches or cavities are created with the UKP laser directly from the 3D model - in just one clamping and without any acting machining forces.

Reproducible parts

The UKP laser works reproducibly with repeatable process parameters, so that one stamp is exactly like another. Even complex 3D shapes can be realized Laser in finished part quality.

Tool breakage? Immediate service!

Stamp breakage and your machine is at a standstill? In emergencies we manufacture replacements as an express service - depending on the urgency as a Express or immediate service.

Your job store for UKP laser chipbreakers

We offer you high technology "on demand" on the latest equipment. Use us as a contract manufacturer and innovation partner for prototypes, samples and series production.

- Discretion in production and development

- Own design department

- Binding delivery dates

- Measurement laboratory with nano-precise measurement technology from Bruker Alicona

Frequently asked questions about chip breakers

What is a chipbreaker?

A chipbreaker is also referred to as a chip breaker, chip guide step, chip guide plate or chip splitter. It is a recess or topology made on (indexable) inserts behind the cutting edge of the tool. Active chipbreakers are used for the best possible chip control, i.e. they influence the shape and serve to remove the chip. HAILTEC undertakes the insertion of chipbreakers into indexable inserts for customers.

How does the UKP laser score in chipbreaker production?

Mechanical processes such as eroding and grinding as well as classic laser technology are accompanied by high process forces and heat influence into the material. The ultrashort pulse laser with femtaser beams avoids temperature influences and produces the best surface qualities, which immensely extends the service life of your tools.