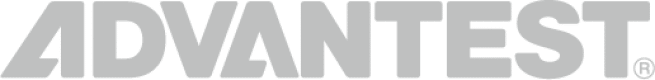

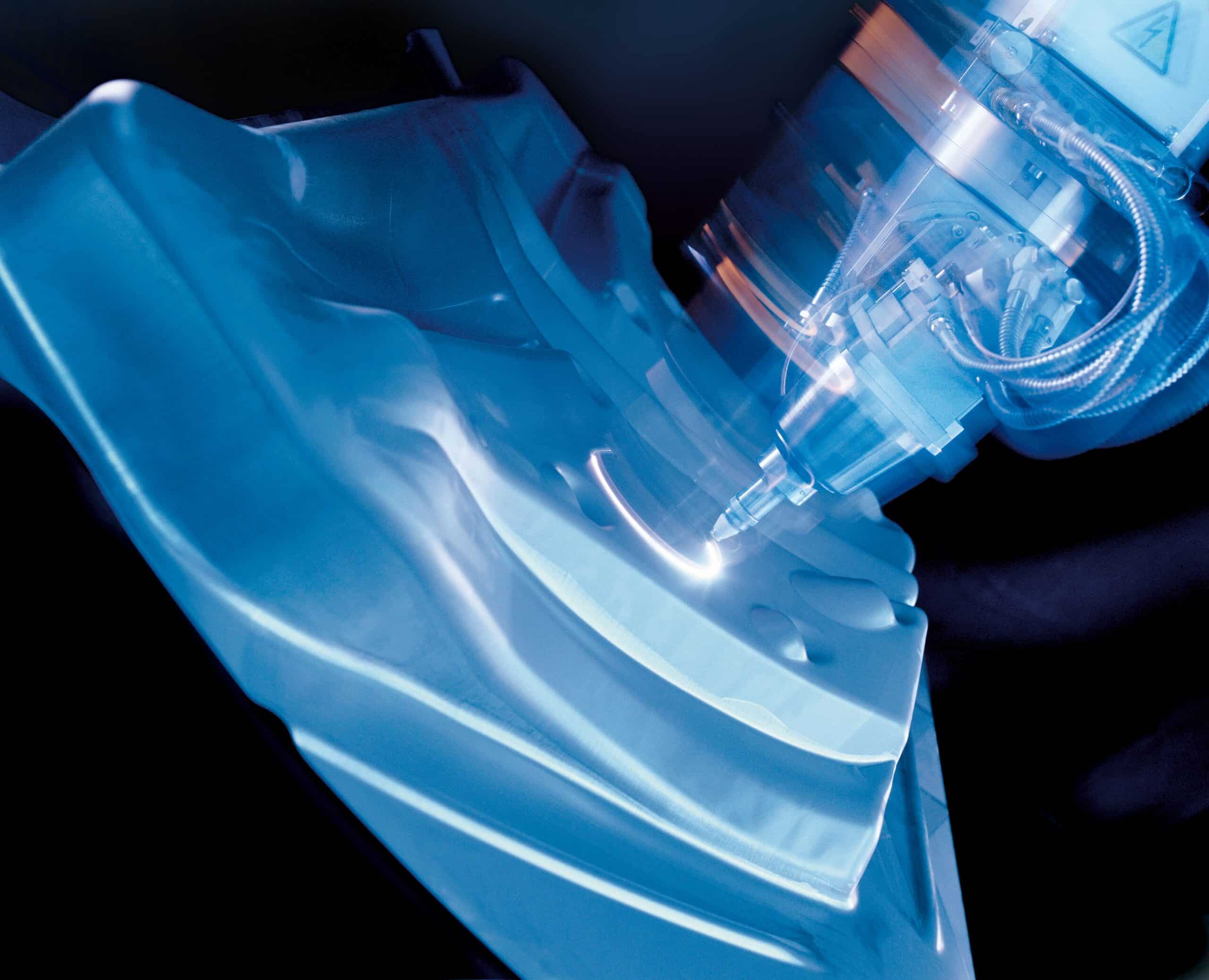

3D laser cutting with maximum precision

PRECISION IN THREE DIMENSIONS | We cut the most complex metal parts to the highest quality

State-of-the-art contract manufacturing of three-dimensional metal parts

Our advanced 3D laser cutting technology is a modern process that enables us to cut even the most complex geometric shapes. the most complex geometric shapes and designs with with exceptional accuracy and speed. Every project is unique and has very different material, size and tolerance requirements. Therefore, we offer customized solutions to ensure that your requirements are met exactly.

No matter whether you prototypes, individual parts or series production we are your reliable partner for precisely manufactured, three-dimensional metal and sheet metal parts up to 5 mm material thickness. Discover our passion for precision and innovation as we turn your ideas into reality with our innovative laser processes.

Source Video: TRUMPF Group

Let's talk about the product you need! Call us now:

Three dimensions. Numerous industries. Endless applications.

3D laser cutting is critical in a wide range of industries, enabling the precise manufacture of parts and products that are often used in a wide variety of applications. At HAILTEC we understand the requirements of different industries and offer customized solutions for example:

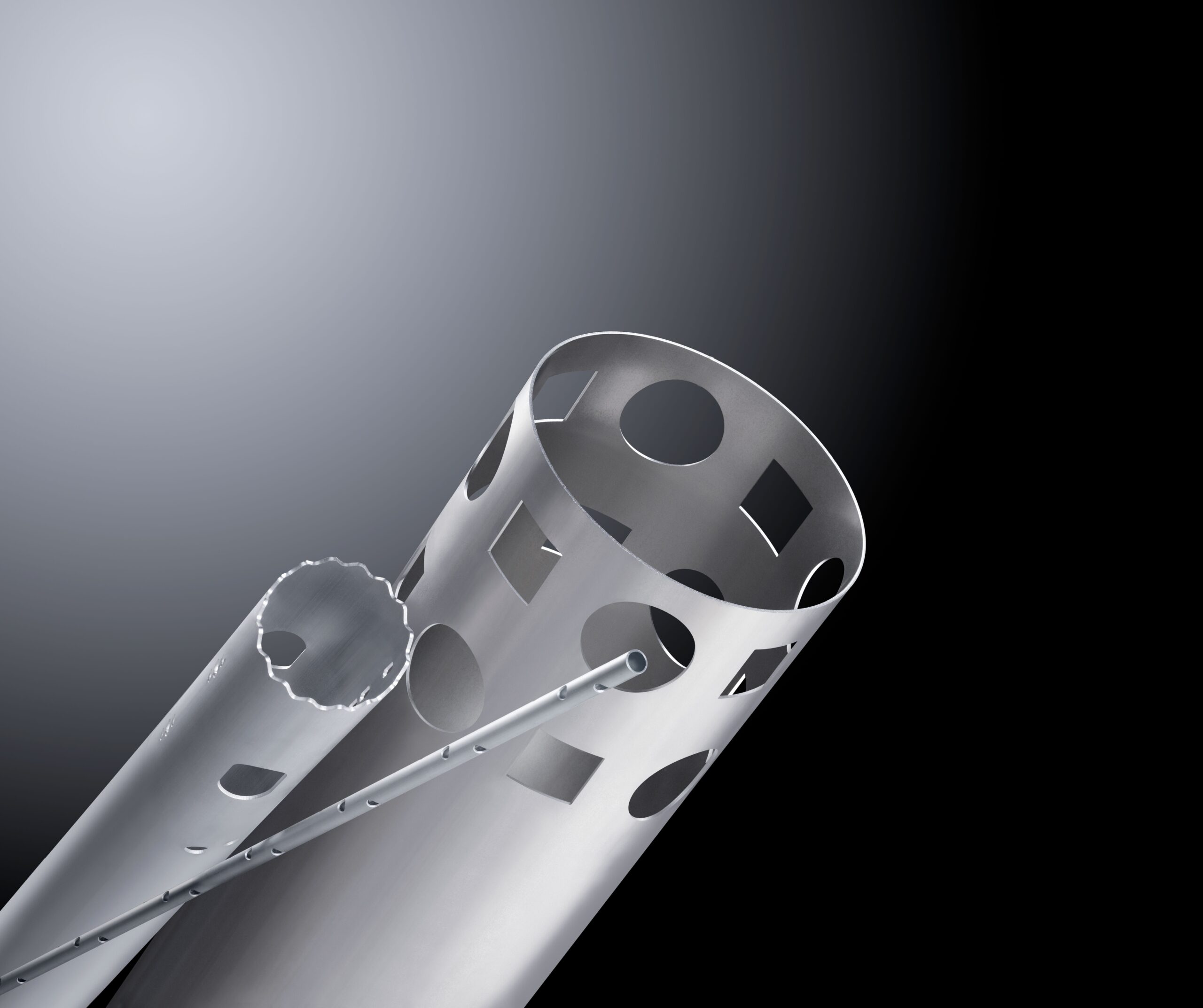

Automotive industry

The manufacturing process is used for the production of connecting parts, small parts, exhaust systems and engine components. Precision and durability are of crucial importance here. The properties of the laser should be precisely matched to this.

3D laser cutting in the aerospace industry

In the aerospace industry, 3D laser cutting is indispensable for the production of complex aircraft parts, from flow-optimized components to lightweight structures. Lightweight materials are primarily used here in order to save weight.

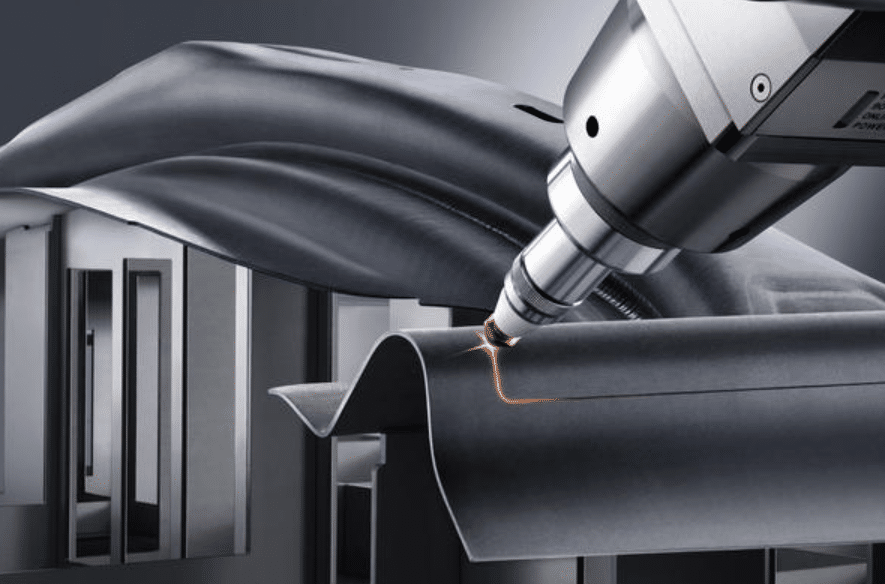

Medical technology

Here, 3D laser cuts are often required for the production of implants, surgical instruments and medical devices. The accuracy and cleanliness of the cuts are essential to meet the highest standards in the healthcare sector.

Other sectors

Whether you work in the electronics industry, mechanical engineering, architecture or construction, we realize your individual challenges and produce high-quality 3D laser cutting solutions.

Source: TRUMPF Group

Source: TRUMPF Group

For which industry do you need our 3D cut-outs? We are always looking forward to new challenges!

State-of-the-art CNC laser cutting machines for complex 3D applications

The key to the precision of 3D laser cutting lies in the control control of the laser beam and its focus on the material. Using the latest computer-aided design (CAD) software, complex cutting patterns and designs can be created. The laser beam melts or vaporizes the material in the desired areas while maintaining the structure and integrity of the workpiece. This process is widely used in industries such as aerospace, automotive, medical technology and many others where precision and high-quality manufacturing are crucial for 3D laser cutting.

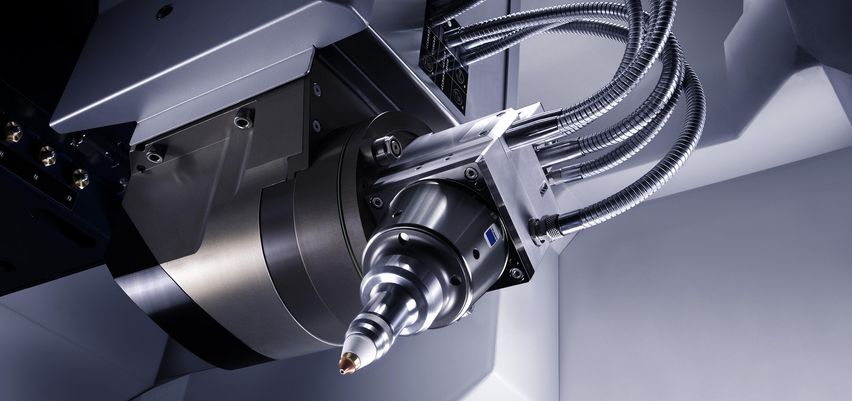

Our 3D laser: TrueCell 3000 from Trumpf

Source Video: TRUMPF Group

Our Trumpf TruLaser Cell 3000 laser is the ultimate solution for multifunctional laser processing. The highlight of this machine is its swiveling laser head and the additional rotary axis, which makes it suitable for tube processing and as a plate. The high-quality machine has a "High Accuracy Package" with a very high axis accuracy. This precision enables us to sheet thicknesses from 0.1 mm to 5 mm and for the laser fine cutting a maximum material thickness of 3 mm is possible.

Our promise to you: One part is like the other. This is ensured by our particularly close monitoring.

3D laser cutting for all technical applications

Would you like to have the most precise component contours 3D laser-cut to an accuracy of 100th of a millimeter? Then you have found your perfect partner! With our high-precision 3D laser fine cutting systems and our decades of experience, we have mastered the cutting of small and fine parts in material thicknesses from 0.1 mm to 5.00 mm.

We monitor the dimensions and punctual delivery of your 3D laser processing orders using intelligent software, digital processes and modern measurement technology. modern measurement technology. This means you can rely on 100% reproducible results.

No matter whether you prototypes, individual parts or series production we are your reliable partner for precisely manufactured, three-dimensional metal and sheet metal parts up to 5 mm material thickness. Discover our passion for precision and innovation as we turn your ideas into reality with our innovative laser processes.

Product examples - 3D laser cutting is often used for this:

- Complex components in the aerospace industry

- Precisely structured parts in the automotive industry

- High-precision medical implants and instruments

- Precision components in electronics production

- Thin and delicate metal or sheet metal parts

- Tubes and profiles with impressive precision

- High-precision and sharp contours in three-dimensional workpieces

Which product do you need? Let's talk about it!

Materials for 3D laser processing

- Steel

- Stainless steel

- Structural steel

- Aluminum

- Titanium

- Copper

- Nickel

- Brass

- Alloys

- Special plastics

- Diamond

- And more - feel free to ask!

Laser cutting from prototypes (sample production) to series production - enquire now!

You have these advantages with HAILTEC

- 100 % reproducible cutting quality

- Innovative and flexible combination of parts

- System supplier: We supply you with the entire product

- High flexibility & short delivery times

- Support with planning & conception

- Competitive prices

- Transparent billing methods

- Ultra-short pulse laser for clean cutting edges

- Digital measurement during production

Source: TRUMPF Group

We are ready for every need and every task - contact us now for a non-binding consultation.

Laser cutting: Why you can rely on our expertise

You can rely on us: As DIN EN ISO 9001 and DIN EN ISO 13485 certified supplier and as a team of capable people. From the dimensions to on-time delivery, we monitor your orders with intelligent software, digital processes and digital measurement technology.

In concrete terms, this means that you can benefit from our our state-of-the-art internal high-tech measuring laboratory instead of having to rely on manual calipers. We use optical 3D measuring systems to precisely measure roughness and shape down to the nanoscale. This gives you 100% reproducible results, whether for quick prototypes or series production.

Our certifications for 3D laser cutting:

We at HAILTEC support you. From the idea and planning to post-production and monitoring. Start your project with us!

FAQ ABOUT 3D laser cutting

What distinguishes HAILTEC from other 3D laser cutting service providers?

HAILTEC sets itself apart from other 3D laser cutting service providers with its outstanding precision. With laser cuts that are up to 10 times more accurate than the industry standard, we set a new quality benchmark. Yes, our prices may be a little higher, but quality pays off. Our high-precision laser cutting means you get perfect results without compromising on accuracy.

What is 3D laser cutting?

In 3D laser cutting, a high-precision laser beam is directed at the workpiece. This laser beam is extremely focused and is moved precisely using computer control. Where the laser beam hits the material, it heats it to such an extent that it melts or vaporizes. This precise process makes it possible to cut complex three-dimensional shapes and fine contours in various materials.

What is the difference between 3D laser cutting and normal (2D) laser cutting?

3D laser cutting differs from conventional 2D laser cutting in its ability to cut three-dimensional objects, whereas 2D laser cutting is limited to flat materials and two-dimensional patterns (e.g. shapes made from 2D sheet metal). This is why other laser systems or lasers are used for three-dimensional laser cutting.