Ultra-short pulse laser ablation

realizes µm-precise embossing forms in carbide, ceramics and tool steel

Your contract manufacturer for ultrashort pulse laser ablation

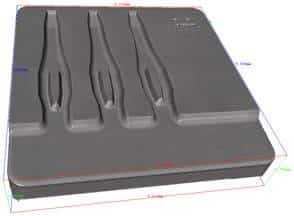

In ultrashort pulse laser processing (UKPL) with the femtosecond laser, we realize filigree 3D shapes (embossing molds) in components and stamp blanks for you. Typical materials are hardened tool steel, powder metallurgical steel or hard metal. These are used to create complex 3D shapes such as press dies, embossing dies, lettering embossers or the smallest cavities.

UKP Laser Ablation, a Real Alternative to Die Sinking Erosion

Advantages of UKP laser ablation

Your contract manufacturer for laser ablation with ultrashort pulse laser technology

UKP laser ablation, the "cold laser processing".

Laser ablation via laser ablation

Laser ablation using ultrashort pulse laser technology is also known as "laser ablation". Here, the material is ablated (vaporized) layer by layer without heating or damaging the base material. With the aid of galvo scanners, the laser beam is guided over the surface of the workpiece with µm precision and very quickly (several m/s), whether in 2D or 3D. This non-contact process is ideally suited for cutting filigree 3D shapes in hard metals, hardened tool steels and ceramics. Due to the advantages of laser ablation, the "laser as a tool" is replacing more and more mechanical processes such as hard milling or die-sinking EDM, since the UKP laser works without tool wear and with extreme reproducibility. Surface roughnesses in finish part quality of up to Ra 0.1µm can be achieved without rework.

In particular, "cold ablation" via ultrashort pulse laser ablation has many applications in areas such as embossing and stamping technology, tool and mold making, medical technology, and the watch and jewelry industry.

Laser ablation with ultrashort pulse laser is ideal for products such as:

Character and number embossers, embossing dies, coin embossers, bending and forming inserts for progressive dies, forming plates, cutting knives and many more

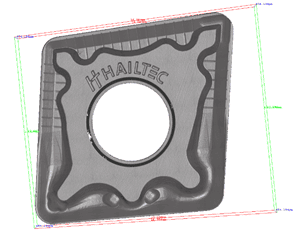

Topology of indexable inserts

- Three-dimensional shape engravings on free-form surfaces

- 3D laser engraving / laser engraving

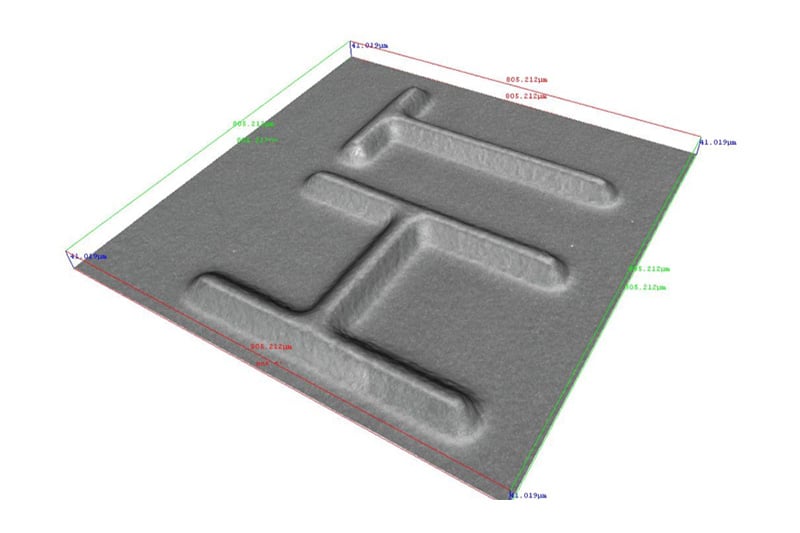

Carbide font embosser

- Material Ceratizit CF H40S

- Depth 35 µm

The UKP laser creates character embossers in the micrometer range for your tools, even in already hardened material.

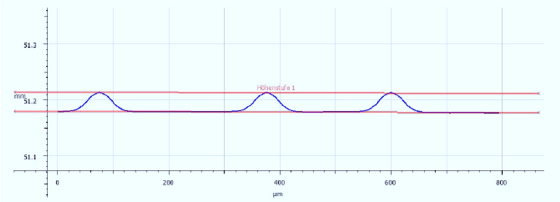

Embossing die Press-in zone

- Material Ceratizit CF H40S

- Surface finishes Ra 0.1 µm

- 10° flank angle

We manufacture your embossing dies quickly and economically, eliminating the need for prior electrode production and reworking.

Laser ablation with ultrashort pulse laser

- fast

- economic

- in outstanding quality