Precision laser cutting

We manufacture your components precisely, economically and on schedule

5 - 10 x more accurate than classic laser cutting

Your reliable contract manufacturer for precision laser cutting

High precision laser fine blanking parts with accuracies of +/-0.01mm

We are your reliable, DIN EN ISO 9001 & 13485 certified contract manufacturer: Our modern, high-precision laser systems and decades of experience enable us to laser filigree laser parts from material thicknesses of 0.05mm - 3.00mm quickly and economically.

Precision laser cutting is 5 - 10x more accurate than conventional laser cutting. Pulsed solid-state lasers apply very little energy to your parts, enabling precision cutting of stainless steel, titanium, copper brass and all common steel alloys.

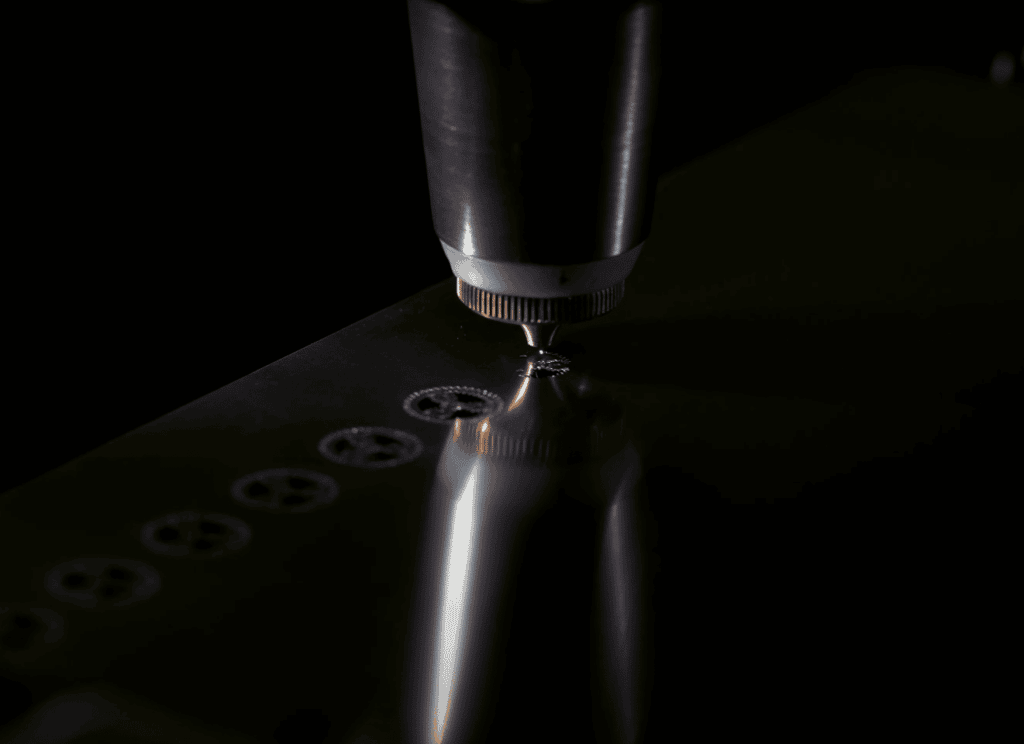

Precise fineblanked parts, efficiently and quickly harvested

Advantages of precision laser cutting

| Precision is measurable: | Precision laser cutting |

|---|---|

| +/- 0.01 mm Contour accuracy* | |

| 0.05 mm - 3.00 mm Material thicknesses that can be cut*. | |

| < 0.025 mm spot diameter* | |

| from 0.025 mm web widths* | |

| from 0.03 mm laser kerf* | |

| max. 800 x 500 mm Dimensions component | |

| *the mentioned values depend on material, thickness and geometry |

4 cutting technologies in house

Regardless of which material you need, in which sheet thickness and with which requirements - we always deliver the right solution. At HAILTEC, we have access to four different cutting technologies: precision laser cutting, micro waterjet cutting, ultra-short pulse laser micro cutting, and punching. Whatever your requirements, we are your reliable supplier and expert for high-precision laser cutting.

Learn more about precision laser cutting now

What advantages does precision laser cutting offer in the manufacture of precision mechanical components and microcomponents?

This white paper highlights precision laser cutting as a non-contact, versatile manufacturing process.

Robot equipped precision laser systems

Your developments are well received on the market and unit sales are skyrocketing?

We automatically produce precise blanks for your implants, lasered precision parts and fineblanked parts with absolute accuracy. In addition, this technology is also perfectly suited for spacer plates, spring plates, shields as well as shims and shim plates in various designs. We manufacture your filigree components reliably and on schedule on µm-accurate precision laser systems with dimensional tolerances of up to +/- 10 µm.

Why are precision laser cutting, micro waterjet cutting and forming technology particularly well suited for prototyping?

What are the benefits of precision laser cutting at HAILTEC?

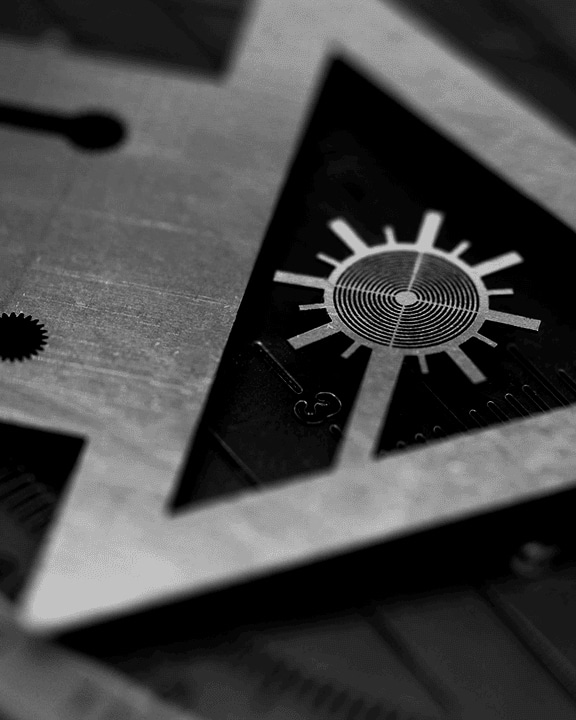

Precision laser cutting: The right choice for your filigree components

HAILTEC has been an expert in precise laser cutting in the field of micromachining with sheet thicknesses from 0.05mm - 3.00mm since 2005. For precise cutting we rely on modern pulsed single and multimode fiber laser sources from DMG MORI and Trumpf. These laser systems introduce very little energy into the material/part due to their technology. Low heat exposure means little distortion and allows filigree cuts in perfect quality . With our precision laser systems and modern beam sources we achieve reproducible fine cuts with spot sizes of 30µm and less. Depending on the sheet thickness, the tolerances are in the range of +/- 0.01 mm. As a reliable contract manufacturer, we not only take care of the cutting, but also deliver your parts with a fine satin finish and absolutely free of burrs.

With machine beds made of mineral casting as well as absolute length measuring devices (glass scale), our precision laser systems are temperature-stable and partially replace wire-eroded sheet metal cutting due to the linear direct drives. Coupled with intelligent process control, in which the power of the laser as well as the nozzle distance to the sheet metal is constantly adjusted and monitored during processing to the respective cutting feed, we thereby achieve contour accuracy. Another advantage of precision laser cutting with HAILTEC: Our laser systems are not classic "flatbed lasers", but havezero-point clamping systems thatallow very short set-up times . This becomes especially necessary for picking up pre-punched strips with press-in zones or for catching individual components.

Quality for your fineblanked parts

HAILTEC produces precision laser cut parts in perfect quality with the smallest tolerances. By using the latest laser technologies and automation systems, as well as our many years of experience, we can offer our customers precision laser-cut parts of the highest quality. The reproducibility is unbeatable with this technology and is 5 - 10 times more accurate than laser cutting: +/- 0.01 mm contour accuracy! "Lasercutting by HAILTEC" is ideal for industries such as medical technology and is also very economical.

Finishing // Surface finish

Certifications

Components in perfect quality

The quality of your precision laser-cut parts is our top priority. At HAILTEC, precision thinking comes first. We are the leading supplier as far as precision laser cutting is concerned. You want to know more about the quality standards as well as the measurement technology at HAILTEC?

10 reasons for precision laser cutting at HAILTEC

Laser processing is an extremely flexible cutting technology for metals. Therefore, this process is particularly suitable for prototypes, small series as well as process-reliable series production.

- Without tool production directly to the sample or series

- Wear and maintenance-free cutting tool

- Low Heat Affected Zone (HAZ)

- Low warpage thanks to low thermal impact

- Finishing-free / -low edges without burrs

- Cutting gap 0.025 to 0.08 mm

- Enables precise, filigree contours

- Fast blank dimension change via CAD/CAM system

- Cutting contours can be adjusted quickly and flexibly

- Tolerances +/- 0.010 mm

Which precision parts can we laser cut for you?

Laser cutting processes at a glance

Keyword fill

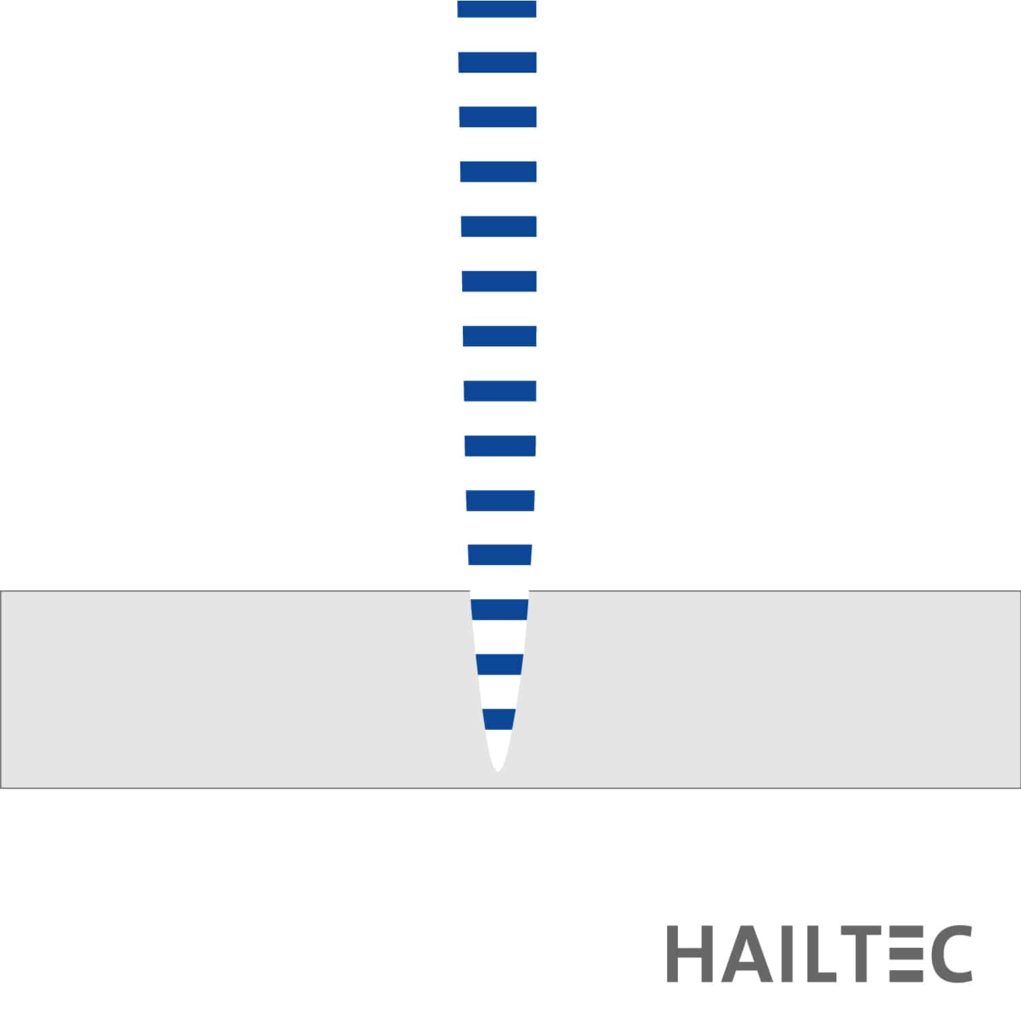

Flame cutting

- low burr formation

- Focus on sheet metal surface

- ideal for carbon steel

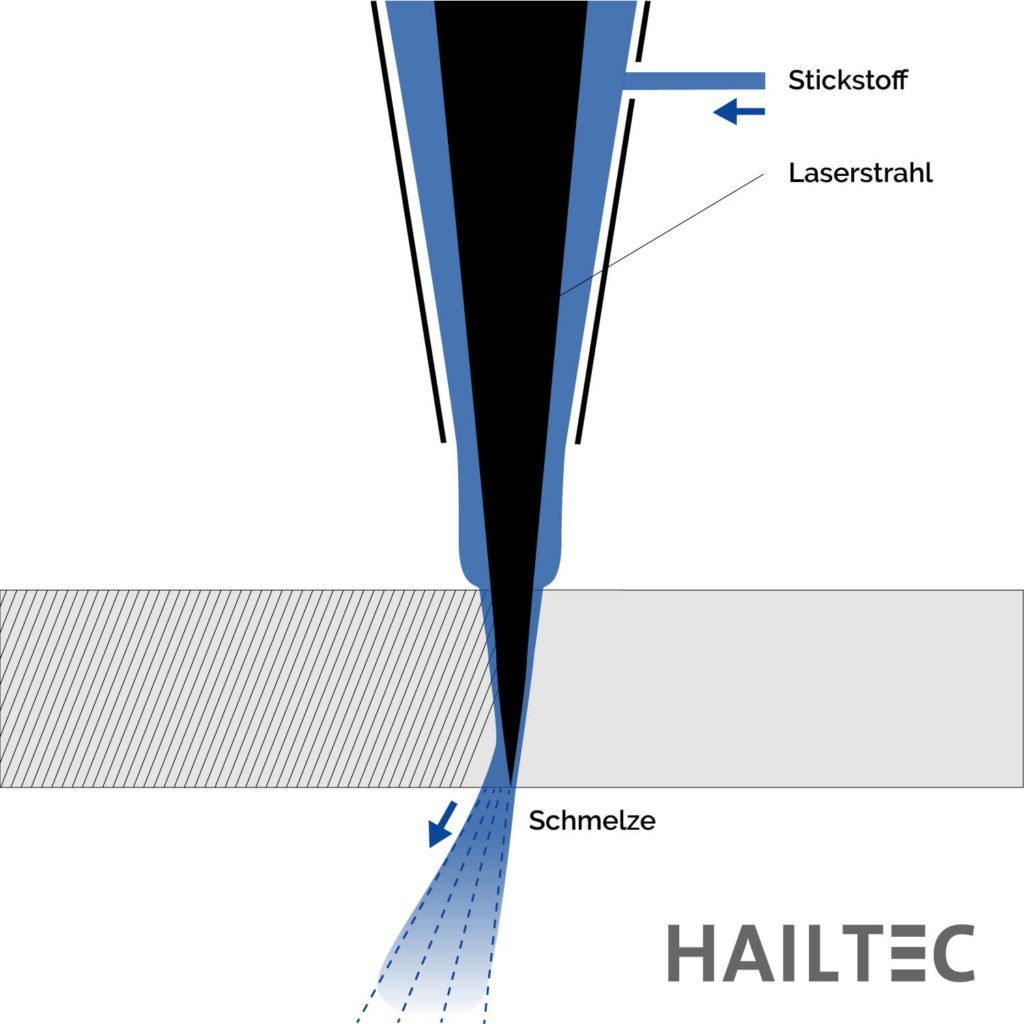

Fusion cutting

- perfect for stainless steel

- Focus on underside of sheet

- burr-free cut edges

Sublimator cutting

- low heat affected zone

- Very low burr

- High accuracy due to galvo scanner

The material for precision laser cutting

Which materials do we process for you in precision laser cutting ?

We produce flat blanks from coil for you on modern precision equipment. Thanks to pulsed laser technology, we cut virtually all metallic materials from sheet metal and foils. From nickel and brass to titanium or nitinol. Please refer to our materials overview to see which materials we can process for you. We are also happy to develop applications according to your specifications.

Sheets and foils - material thickness: 0.05 mm - 3.00 mm

Here you will find an overview of materials for precision laser cutting - Which material do you need?

Stainless Steel // Stainless Steel Foils

Copper // Copper foils

Brass // Brass foils

Nickel // Nickel foils

Titanium // Titanium foils

Aluminum // Aluminum foils

Carbon steel // Steel foils

Bronze // Bronze foils

Tantalum // Tantalum foils

Hilumin

Ceramics

Diamond // PCD

Precision laser cutting is ideal for products such as:

Laser cut implant

- oxide-free cut edges

- precise and economical

- ideal for laser cutting of titanium grade 2

Precise precision mechanical components

- smallest web widths possible

- ideal for spring steel strip 1.4310

- Cutting tolerance up to +/- 10 µm

Why is HAILTEC the right partner for your industry?

As a supplier, we fulfill your desire for maximum reliability in precision laser cutting with excellent beam quality and very small spot diameters. We feel particularly at home in the following industries:

- Tool and mould making

- Aerospace

- Measurement and control technology

- Watch industry

- Model making

- Embossing and punching technology

- Medical technology

- Automotive

- Mechanical Engineering

- E-mobility

- Electrical industry

- Micro / precision engineering

Member of networks and associations

HAILTEC - Your certified partner

Frequently asked questions about precision laser cutting

Can HAILTEC also do robotic precision laser cutting?

Robotic support enables us to be a reliable and economical partner for you, even for large quantities. With mobile robot cells, we run autonomous shifts and manufacture your large-volume orders even faster and more efficiently. Because accuracy is the measure of all things in precision laser technology - the combination of temperature-stable mechanical engineering, intelligent process monitoring in real time paired with automated placement by robots. This additionally ensures speed and throughput at HAILTEC.

What is the difference between laser cutting and precision laser cutting?

Precision laser cutting works with pulsed laser energy. This means that high peak pulse powers and a large power density are generated on the surface of the workpiece. Due to the high power density, the material is melted and vaporized. While "classic" laser cutting in CW mode cuts extremely fast, pulsed laser systems are suitable for delicate geometries and introduce very little heat to the workpiece. Lower heat, of course, means lower feed rates, but for laser-cut components focused on quality, the focus is on accuracy. The achievable tolerances of laser cutting to precision laser cutting are in the ratio of 1:5 to 1:10.

Is it possible to cut on filigree contours with precision laser cutting?

The pulsed laser beam heats the material only locally, the thermal load in the workpiece is low. The kerf is similarly narrow as the beam. Why is this important? It makes it possible to cut complex contours, smoothly and without burrs. This eliminates the need for time-consuming reworking. After precision laser cutting, satin finishing gives the workpieces a perfectly brushed surface.

Laser or water: Which cutting technology is ideal for you?

Together we will determine which technology will produce the best results for you: precision laser cutting, micro waterjet cutting or ultra-short pulse laser micro cutting. The decision depends heavily on the material and the desired result. Precision laser cutting is often recommended for thin sheets and 2D and 3D shapes, while micro waterjet cutting and the UKP laser cut sensitive materials and complex geometries without thermal stress. Due to the exceptional technology breadth at HAILTEC, you benefit from the optimal and economical manufacturing process in every case.

What are the functions of the precision laser systems at HAILTEC?

In the precision laser cutting center you will find ideal conditions for your requirements and precise components:

Intelligent process monitoring

- Active laser power measurement

- Distance sensor technology

- Precise positioning and control of machine axes

Specifications

- Pulsed laser power from 80 to 3000 watts

- 2D and 3D laser cutting and welding

- Spot sizes from 25 to 185 μm flexibly variable thanks to beam shaping optics

- Sheet thicknesses 0,05 - 3.0 mm

- High-resolution camera system for precise recording of your individual parts

- EROWA zero point clamping systems.