Forming technology

We bring your small, fine parts into shape

Forming technology? HAILTEC!

You need a forming professional for your precision components? You've come to the right place: Agile and experienced, we accompany you from batch size 1 to series production. For sheet thicknesses from 0.1 to 5 mm and components up to 500 mm, we check the feasibility, form completely and ensure 100% quality with digital optical measuring systems. CAD development, CNC machining, automatic punching machines, toggle presses, swivel bending, folding or hydraulic presses: You will find everything under one roof, certified and process experienced.

4 separation processes, 1 supplier

How can you be sure of always getting the best and most economical result? With a contract manufacturer that is technologically broadly positioned: From quick samples to series production, we always use the optimum process for you. Depending on sheet thickness and requirements, you can rely on our expertise with four in-house cutting processes:

Punching, laser fine cutting, micro waterjet cutting or micro cutting

4 separation processes, 1 supplier

How can you be sure of always getting the best and most economical result? With a contract manufacturer that is technologically broadly positioned: From quick samples to series production, we always use the optimum process for you. Depending on sheet thickness and requirements, you can rely on our expertise with four in-house cutting processes:

Our DNA "Everything under one roof" ensures you the best quality and fixed deadlines

Advantages of forming technology

Your partner for precise prototypes and small batches

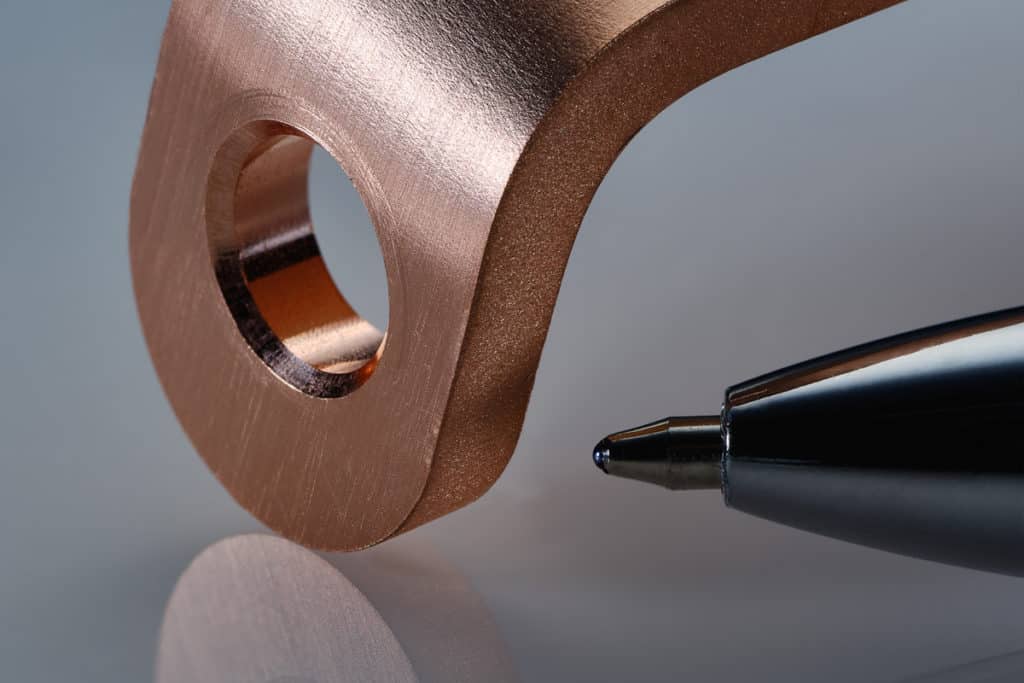

Forming Technology Product Examples:

Enter your headline here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Rational and versatile we manufacture for you for example:

- Contact parts / pins / tabs

- Punched grid (also laser cut)

- Springs, brackets

- Fasteners

- Precision components such as busbars

- Micro components with forming

- Complex geometries

Whether prototypes, small or large quantities: You can count on high-grade and consistent quality. We deliver worldwide, with a focus on the "stamping region" around Pforzheim and the entire DACH area.

Enter your headline here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Why HAILTEC has the right technology for you

View into the machine park

Bending & Forming Technology

Hydraulic presses up to 40 t

Toggle presses up to 2.2 t

Pneumatic presses up to 20 t

Tolerances according to DIN ISO 2768 mk, finer by agreement

Micro Precision Swivel Bending Machine

Punching technology

40 t press

Servo feed

Installation space 500 x 400 x 300 mm

Sheet thickness up to 2.5 mm

Forming technology: Industries

The smallest forming, embossing, beading or curved free-form surfaces with minimal tolerances: In industries such as medical technology, precision sets the tone. As a DIN EN ISO 13485 certified contract manufacturer, we have been meeting this requirement for years. For customers in mechanical engineering and e-mobility, we produce precision components such as busbars, cell connectors, shielding foils and covers.

- Tool and mould making

- Aerospace

- Measurement and control technology

- Watch industry

- Model making

- Embossing and punching technology

- Medical technology

- Automotive

- Mechanical Engineering

- E-mobility

- Electrical industry

- Micro / precision engineering

Whether prototype, sample or series: The all-round service from your trusted supplier saves you time, costs and nerves.

Your expert in forming technology

Why HAILTEC deserves your trust

We accelerate your sample production thanks to our own tool shop, design department, well-established workflows and unique technology mix. We guarantee batch traceability and reproducible quality from the initial sample through to series production. Sampling is possible at any time - we take care of all work steps for you.

With four in-house cutting technologies, you always get the optimum result: We cut your steel parts with the laser in thicknesses from 0.1 mm to 3 mm, and with the micro waterjet also sheets up to 5 mm. Cutting is followed by forming as well as stamping, settling, combined machining or fitting bores. For special surface finishes, erosion, CNC machining or whatever is necessary to meet your requirements.

Frequently asked questions about ultra-short pulse laser technology

For which products is microcutting with the UKP laser suitable?

- Micro spring element

- Micro watch hand

- Micro gears

SEM recording of the cut edge quality UKP laser micro cutting

REM mount fitting hole 0.8mm H7

Micro mountain bike next to a two-euro coin:

In UKP micro laser cutting (also called micro laser cutting or laser micro processing), the UKP laser realises miniaturised shapes with micrometre-fine ridges and cuts.

Product examples for medical technology

Examples of applications for UKP laser microcutting for medical technology are minimally invasive surgical instruments such as microscalpel and surgical needles, atomiser nozzles, bone saws, etc.

What added value does ultrashort pulse laser technology bring to laser micromachining?

Burr-free and µm-accurate

Cutting edge roughness up to Ra 0.2 μm

Almost right-angled cut edges