Lasered embossing dies metal and carbide

Downtime up, costs down

For you we manufacture µm-precise lasered embossing dies

Millions of strokes per day put a strain on mold components such as embossing punches or dies. Wouldn't it be good to significantly increase their service life? Well-known companies in the embossing and stamping technology industry rely on our expertise as a supplier: We use ultrashort pulse laser technology to manufacture your embossing dies quickly and reproducibly - on the same day if you are in a hurry.

Added value for your embossing dies

With the help of HAILTEC's ultra-short pulse laser processing, you minimize your machine downtime, save costs and shorten your production time. You obtain surface qualities down to Ra 0.1 µm - and avoid the disadvantages of die-sinking EDM (see table below).

All advantages at a glance

Die-sinking EDM

vs. ultra-short pulse laser machining

Die-sinking EDM has long been the standard for introducing embossing contours into carbide tools. In comparison, the ultrashort pulse laser technology scores: The electrode production is omitted, which makes the manufacturing easier and more precise. This is because neither wearing electrodes nor a rougher surface finish (due to die-sinking erosion) affect the carbide surface.

| Advantages | Ultra-short pulse laser | Die-sinking EDM |

|---|---|---|

| Residual compressive stresses counteract the formation of cracks | ||

| Cold material removal prevents, among other things, melting zone on the surface ("white layer") | ||

| Shortened process time (no electrode production necessary) | ||

| Reproducible results | ||

| Surface finish up to Ra 0.1 µm | ||

| High-precision cavities with flank angle up to 10°. | ||

| Inside corner radii up to 0.03 mm | ||

| Opens up freedom of material and geometry |

Ultra-short pulse laser technology increases the service life of your embossing dies by a factor of up to 10

CERATIZIT & HAILTEC: Whitepaper

In a series of tests CERATIZIT Empfingen GmbH and HAILTEC,

show how ultra-short pulse laser machining gives embossing punches a significantly longer tool life than conventional die-sinking EDM.

Would you like to learn more about the results of the test series carried out by CERATIZIT Empfingen and HAILTEC? Click here for the informative white paper:

Product examples embossing stamp

Font embosser, die, etc.

Examples of the quality and products of laser microcutting

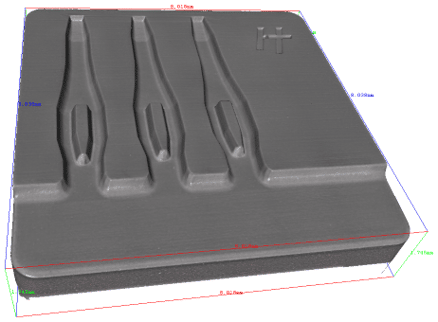

Embossing punch for press-in zones

µm-precise machining of a Hartmtall CF-40S from Ceratizit

- Flank angle up to 10° possible

- Position tolerance blank/laser contour +/- 0.005 mm thanks to high-resolution CCD camera and tactile probe for blank alignment

- Contour depth 400 µm

- Surface roughness 0.102 µm

With the UKP laser, high-precision embossing dies succeed without additional tools or electrodes.

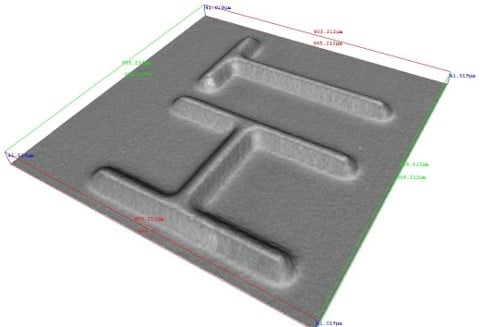

Font embosser

Fast and with a long service life, we produce the smallest shapes for you in your embossing dies.

- Contour depth 100µm

- Long service life due to gentle machining

Enter your headline here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

How to score with ultra-short pulse laser technology from HAILTEC

Plus points for your embossing and die cutting technology

More speed and quality

Thanks to "cold" laser processing, we manufacture your embossing dies particularly quickly and precisely: On precision machines from DMG MORI and TRUMPF with Tolerances of +/- 0.005 mm.

Molds directly from 3D model

Your molds, dies, bending punches or cavities are created with the UKP laser directly from the 3D model - in just one clamping and without any acting machining forces.

Reproducible parts

The UKP laser works reproducibly with repeatable process parameters, so that one stamp is exactly like another. Even complex 3D shapes can be realized Laser in finished part quality.

Tool breakage? Immediate service!

Stamp breakage and your machine is at a standstill? In emergencies we manufacture replacements as an express service - depending on the urgency as a Express or immediate service.

Your job store for UKP laser embossed stamps

We offer you high technology "on demand" on the latest equipment. Use us as a contract manufacturer and innovation partner for prototypes, samples and series production.

- Discretion in production and development

- Own design department

- Binding delivery dates

- Measurement laboratory with nano-precise measurement technology from Bruker Alicona

Frequently asked questions about embossing dies

What added value does ultrashort pulse laser technology bring to your embossing and punching technology?

As a manufacturer of progressive dies, you want to avoid machine downtime and thus save costs. This is where we come in: With the help of ultrashort pulse laser technology, we give your stamping dies a significantly longer service life.

How does the UKP laser increase the service life of your embossing dies?

Millions of strokes per day are a stress test for wear-intensive tool components such as embossing punches for press-fit zones, connectors or micro-number embossers. In a joint test series with carbide manufacturer CERATIZIT Empfingen we were able to demonstrate: Ultra-short pulse laser machining gives embossing punches a service life that is up to a factor of 10 longer than that of die-sinking EDM.