Measurement technology down to the nanoscale

You can measure us by the quality

Your expert for measurement technology

You need the quality of your filigree components in black and white? Our in-house measurement laboratory provides you with the data for your quality assurance. From the area-based 5-axis system from Keyence to the nano-precise surface measurement in 3D from Alicona - your high-end products are in the best hands at HAILTEC.

That's why HAILTEC is your partner for measurement technology

Measurement technology: your added value

Measurement laboratory at a glance

Alicona Infinite Focus Advanced Real 3D - IF Ringlight HP

Schneider PMS 400 - optical and tactile coordinate measuring machine

Keyence VHX Measuring Microscope

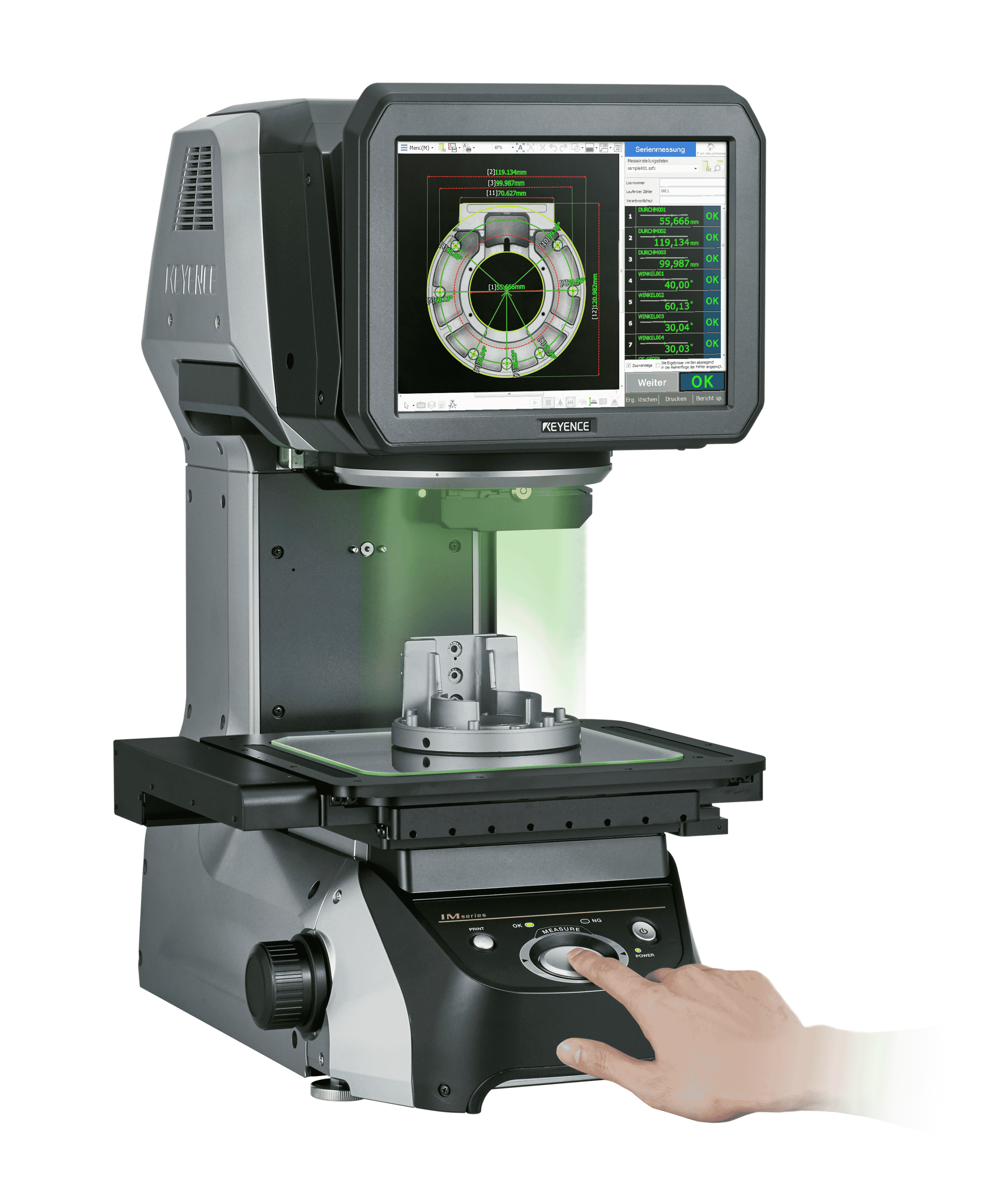

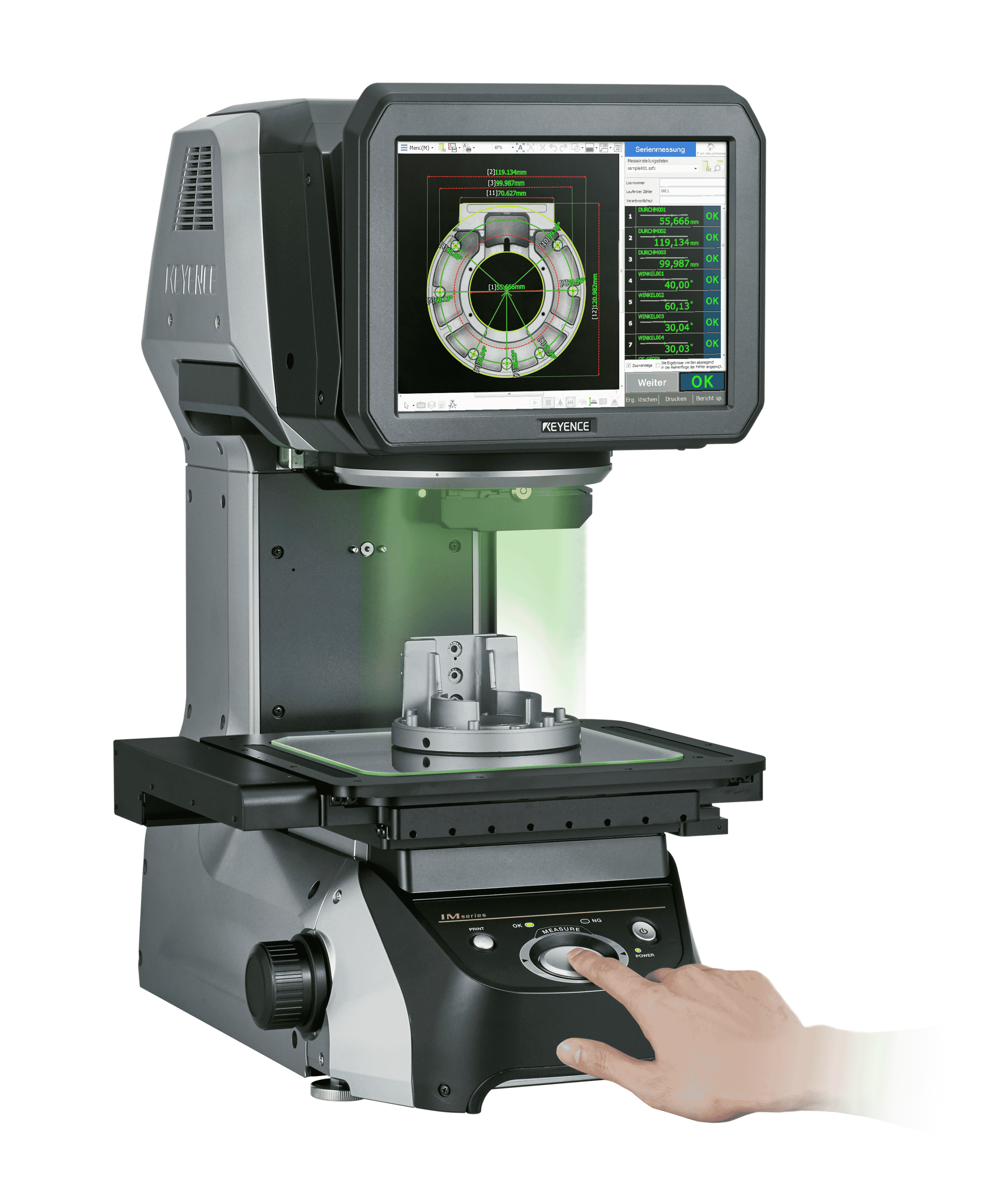

Keyence IM series - IM H2ED

Mitutoyo measuring and profile projector

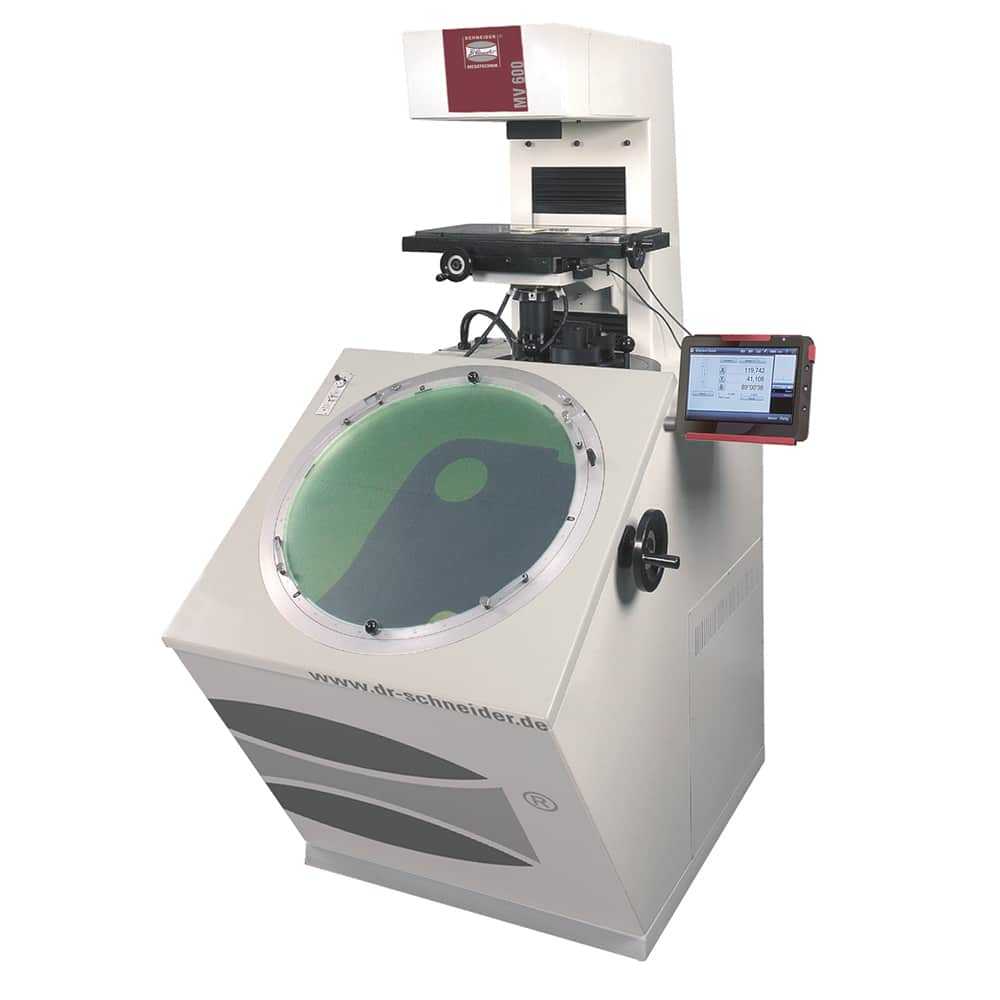

Schneider measuring and profile projector

Measurement technology you can rely on

Examples of measurement tasks:

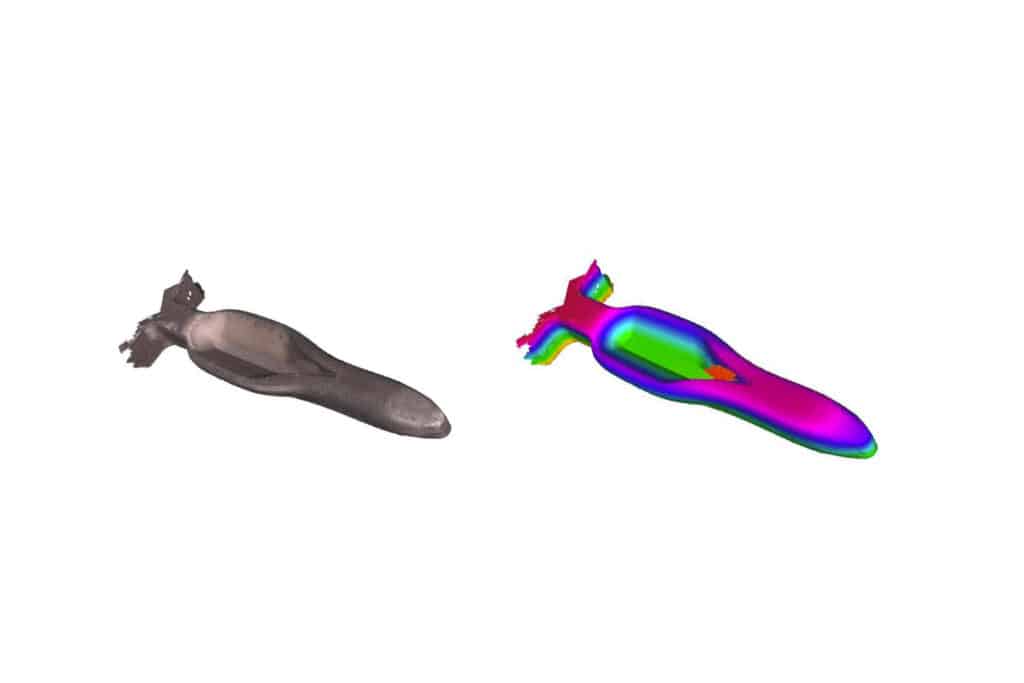

Press-in zone Stamped part

The optical 3D measurement simplifies the target/actual comparison by means of color-coded display:

- Measuring field size: 5.90 mm x 1.90 mm x 1.30 mm

- Number of measuring points: 0.6 Mio

- Vertical resolution: 400 nm

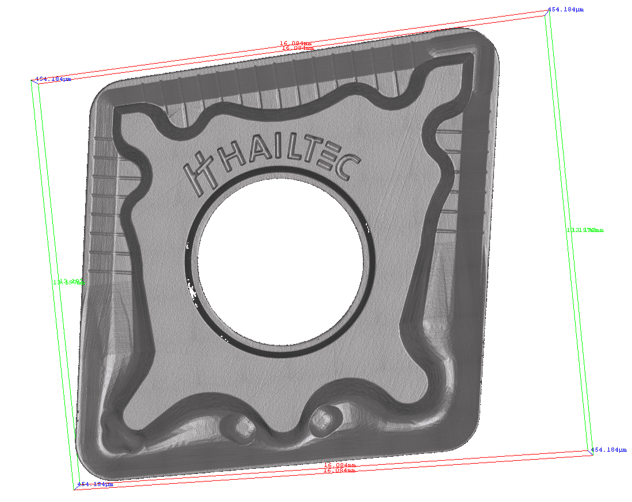

Topology of an indexable insert

Optical measurement can be used to check molds for dimensional accuracy very easily

- High resolution for detailed measurement

- Easy measurement of shape and surface roughness

- Vertical resolution: 400 nm

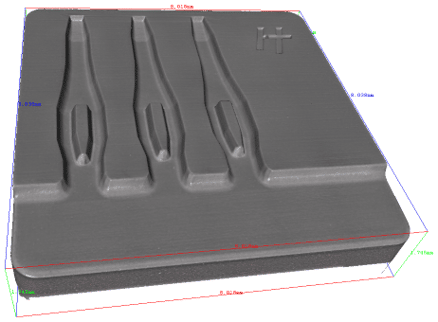

Measurement of an embossing die by means of focus variation

We check molds simply and quickly by means of target/actual comparison

- Fast and repeatable measurement

- Export of a STL data set possible

Use nano-accurate measurement technology as a service

Further services at HAILTEC

Metrology: Services for your success

Measure roughness and shape

The optical surface measuring device from Bruker Alicona analyzes the smallest components without contact and thus without damaging the material. It detects deviations down to the submicrometer and nanometer range.

Reverse engineering

You have a component, a stamp or a coin - but no data? With the help of high-precision measuring equipment, we create CNC data from samples and digitize your 3D shape, even in the µm range.

Sampling

Upon request, we will provide you with an initial sample inspection report (EMPB), which guarantees consistent quality.

Your address for nano-precise measurement technology

As Germany's leading job store for ultrashort pulse laser processing, we also offer high-end measurement technology openly as a service. Because anyone who uses microfine components needs quality measured down to the submicrometer.

We manufacture them for you - and prove them with the help of nanometric surface measurements. Finally, our in-house measurement laboratory is the heart of our quality management. Among other things, we rely on the high-precision and universal optical 3D measuring system µCMM from Bruker Alicona.

- fast

- economic

- high-precision

Frequently asked questions about measurement technology

What measurement technology does HAILTEC use?

With a multi-sensor coordinate measuring machine (optical and tactile combined) from Keyence, we measure the quality of your components during production.

Bruker Alicona µCMM is a high-end 3D surface measuring instrument without equal. It is non-contact, gentle on your materials and detects roughness and deviations in the range of micro- and nanometers.

Does HAILTEC only miss components from its own production?

No, we offer 3D measurement technology as an open service.

In addition, we measure your components optically during production and thus guarantee quality in accordance with specifications.

We quickly and reliably re-measure any shape or surface you require. On request, you will receive different measurement reports and digitized data of your material surfaces in 3D.