Your contract manufacturer for laser cutting

As a contract manufacturer for laser cutting, we take it very seriously:

With high-precision laser cutting systems and decades of experience, we cut small, fine parts for you in material thicknesses of 0.1 mm - 5.00 mm and with dimensions of up to 800 x 500 mm reliably, quickly and economically.

What distinguishes the process at HAILTEC from other suppliers?

From the dimensions to on-time delivery, we monitor your orders with intelligent software, digital processes and digital measurement technology.

In concrete terms, this means that instead of manual calipers, you benefit from our in-house high-tech measuring laboratory. We use optical 3D measuring systems to measure roughness and shape down to the nanometer range. This gives you 100% reproducible results. From a quick prototype / sample to series production. You can rely on us: As a DIN EN ISO 9001 and DIN EN ISO 13485 certified supplier and as a team of capable laser technology enthusiasts.

HAILTEC's technology arsenal includes a wide range of cutting processes such as punching, laser cutting, laser fineblanking and micro water jet cutting.

"Our credo: The right process for every job." Alexander Renz, Managing Director of Hailtec GmbH

Advantages of the laser cutting process

- 100 % reproducible cutting quality

- High flexibility and short delivery times for individual parts and series

- Competitive prices and transparent billing methods

- Pulsed laser beams for burr-free sheets and clean cut edges

- Digital measurement during production

How does laser cutting work?

Laser cutting is a thermal separation process in which materials are cut through with a laser beam. The process uses the high energy of a laser beam to melt, vaporize or blow away materials to create a cut.

Laser cutting is one of the most flexible processes for cutting sheet metal and other materials. Speed, precision and exact cutting edges plus a wide range of applications make laser cutting so efficient and widespread. At HAILTEC, we have specialized in the laser cutting of particularly fine, precise components with dimensions of up to 800 x 500 mm since 2004. This so-called laser fine cutting is 5-10 times more precise than conventional laser cutting.

What can you do with laser cutting?

Versatile application options for different materials

Which materials and substances do we process for you with laser cutting? We produce flat laser cuts for you directly from the coil. Thanks to pulsed laser technology, we can cut almost any metal as well as other materials and foils. Typical material thicknesses for sheet metal and foils range from 0.1 mm to 5.00 mm.

The materials overview shows which materials we can process for you with the laser beam. We are happy to develop applications according to your specifications. Here you will find an overview of typical materials for laser cutting:

Laser fineblanking - plant in portrait:

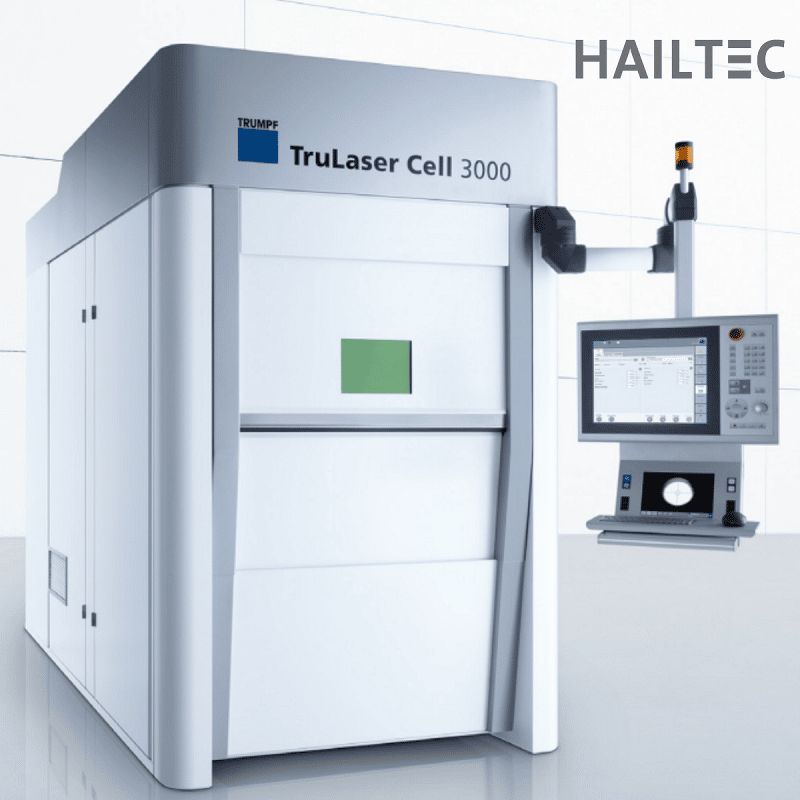

3000 watts for laser fine cutting:

The TruLaser Cell 3000 is one of the precise power packages in the HAILTEC machine park. We use this multi-talent for three processes:

- 2D laser fine cutting

- 3D laser fine cutting

- Laser welding

With its five axes, the laser cutting machine realizes filigree applications in sheet metal up to five millimeters thick quickly, economically and with high precision.

With the automated laser fine cutting system, the laser power can be measured after the protective glass following processing. Ensuring exact dimensional accuracy:

- 100 percent process control (important especially in precision mechanics and medical technology)

- High Accuracy Package

- water-cooled linear direct drive

- Beam shaping optics

- Stainless steel

- Stainless steel foils

- Copper // Copper foils

- Brass // Brass foils

- Nickel // Nickel foils

- Titanium // Titanium foils

- Diamond // PCD

- Aluminum // Aluminum foils

- Carbon steel // Steel foils

- Bronze // Bronze foils

- Tantalum // Tantalum foils

- Hilumin

- Ceramics

Well-known customers from the industry rely on HAILTEC's expertise:

Precise material processing with the laser is ideal for precision mechanical components and products such as:

Precise implant blanks, laser-cut precision parts, fineblanked parts, spacer plates, spring plates, shields, shim plates as well as shims and compensating foils.

Laser cut implant

- oxide-free cut edges

- precise and economical

- ideal for laser cutting of titanium grade 2

Precise precision mechanical components

- smallest web widths possible

- Ideal for materials such as spring steel strip 1.4310

- Contours with tolerances of up to +/- 10 µm

Efficient and fast cutting from batch size 1 to series production

Do you need large quantities quickly? You can scale easily with us. Automated laser cutting makes it possible. In our Laser Center, we produce your metal parts with contour accuracies of up to +/- 10 µm. And from quantities of 1 to 500,000.

- Economical even under time pressure

- Reproducible and traceable

- Transparent, digital workflow

We strive to become better and better for you. That's why we rely on robotic support right from the start, so that we can offer you a fast service even for large quantities. Using a docking station, the robot can be used on different processing systems as required - for example, for precise laser cutting, where exact dimensions are essential. Automated loading by robot is ideal here, as it ensures both speed and reliable processes.

Automation with robots offers you numerous advantages:

- Robot technology opens up flexible production capacities and autonomous shifts - this means we can also quickly push in an order under time pressure

- We manufacture your components efficiently and economically in a range from single units to 200,000 pieces

- Digital and automated production guarantees dimensionally accurate quality and reliable processes

- We enable short delivery times with a unique combination of expertise, technological advantage and lean processes

Measurable precision according to your individual requirements

| Precision is measurable: | Laser cutting |

|---|---|

| +/- 0.02 mm exact contours* | |

| 0.1 mm - 5.00 mm cuttable material thicknesses* | |

| 0.025 mm spot diameter* | |

| from 0.025 mm web widths* | |

| from 0.05 mm laser cutting gap* | |

| max. 800 x 500 mm Dimensions* | |

| *the mentioned values depend on material, thickness and geometry |

Do you need it even finer?

Discover the laser fineblanking and ultrashort pulse laser machining processes at HAILTEC

Pulsed laser systems for precise and clean cutting

For precise laser cutting, we use QCW pulsed fiber lasers and Nd:YAG laser systems from renowned manufacturers such as DMG MORI and Trumpf in our production. What distinguishes these laser sources? They introduce very little energy into the material. Little heat means little distortion and enables filigree cuts.

Using laser systems and modern beam sources, we achieve reproducible cuts of 0.05 mm gap width and less. Depending on the metal and sheet thickness, the tolerances for laser cutting are +/- 0.02 mm. As a contract manufacturer, we can carry out surface processing such asdeburring or satin finishing of your parts on request.

Your one-stop supplier for laser fine cutting

We can do it completely

Several process steps pass from the raw material to the finished packaged part. It's good when you can rely on a supplier. From A to Z, we go the extra mile for you. That saves time, money and interface hassle. And it has earned us the status of A-supplier with many well-known manufacturers.

- In-house tooling and design department simplifies the production of your prototypes and samples

- Feasibility study included as well as technology consulting

- Precisely shaped components without burrs or hooks laser precision cutting

- Batch traceability and reproducibility

- Surface finish of your components

The TruLaser Cell 3000 is one of the precise power packages in the HAILTEC machine park.

We use this all-rounder for three laser technology processes:

1. 2D laser cutting

2. 3D laser cutting

3. Laser welding

With its five axes, the laser cutting machine can carry out intricate applications in sheet metal up to five millimetres thick quickly, economically and with high precision.

The automated laser cutting system allows the laser power to be measured after processing according to the protective glass. Ensure precise dimensional accuracy of your components:

- 100 percent process control (important especially in precision mechanics and medical technology)

- High Accuracy Package

- water-cooled linear direct drive

- Beam shaping optics

HAILTEC - Your certified partner

Experienced and trained employees for the highest quality standards

We take quality very seriously: precision thinking is deeply rooted at HAILTEC. We are the A supplier for high-precision laser cutting.

Laser cutting on a contract basis with HAILTEC: simple procurement, high quality

"If you're looking for experts in laser cutting on a contract basis, you've come to the right place. With us, procurement is not only easier, but also more effective."

Quick caculation.

We know how valuable your time is. That's why we offer a rapid calculation of your individual inquiries so that you can make quick and well-founded decisions.

Flexible delivery:

With us, you have the freedom to choose your desired delivery date so that your production runs smoothly.

Everything from a single source:

Our extensive manufacturing processes guarantee that you will find all the services you need under one roof. From laser cutting to specialized machining processes - we have it all.

Versatile further processing:

We offer far more than just flat cuts. After cutting is before finishing: take advantage of our versatile further processing methods such as machining, forming technology and surface finishing.

Single part production made easy:

Whether prototypes or individual components - single-part production is no problem for us.

Wide range of materials:

Our unbeatable range of materials enables us to fulfill a variety of requirements directly.

Experts at your side:

Our team consists of qualified specialists who know their trade and will get the best out of your project.

Top modern equipment:

Our state-of-the-art machinery is ready to achieve the best possible results for you.

What types of laser cutting are there?

There are big differences in laser cutting. The laser tool cuts without contact and universally thanks to different cutting processes.

Keyword fill

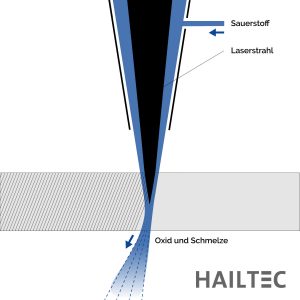

Flame cutting

How does flame cutting work?

In flame cutting or laser cutting, oxygen is blown into the kerf at a pressure of up to 20 bar. This enables a very high cutting speed, as the energy generated during combustion accelerates the cutting process. One drawback of the otherwise inexpensive and economical laser cutting process is that flame cutting introduces a lot of heat into the component.

- low burr formation

- Focus on sheet metal surface

- ideal for carbon steel

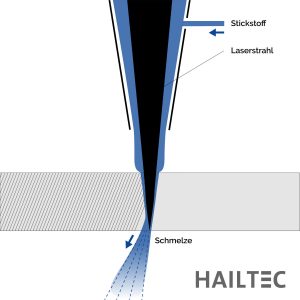

Fusion cutting

How does fusion cutting work?

Laser fusion cutting is a cutting process using a solid-state laser. For laser fusion cutting, a reaction-inhibiting cutting gas (argon or nitrogen) is pressed into the kerf at a pressure of up to 23 bar. The gas cools and prevents oxidation at the cut edge of the sheet metal.

- perfect for stainless steel

- Focus on underside of sheet

- burr-free cut edges

Sublimator cutting

How does sublimation cutting work?

Laser sublimation cutting is a process in which the material is vaporized with as little melt as possible. The vaporizing material generates high pressure in the kerf, which causes the molten material to be ejected. The process gas keeps the cut edges free of oxide.

- low heat affected zone

- Very low burr

- High accuracy due to galvo scanner

Aluminum is a relatively soft and light material, resistant to corrosion and easily weldable. Typical material grades:

- AW-5754 / AlMg3

- AW 6082 / AlSi1MgMn

- AW-1050A (pure aluminum)

Titanium (Ti) is lightweight, biocompatible and passivatable. We often use the material for medical technology.

- Structural steel (material grades e.g. 1.0330, DC01 or 1.0338, DC04)

- Stainless steel (standard stainless steels V2A such as 1.4301, 1.4316; stainless steels V4A such as 1.4404, stainless steel 1.4828, 1.4016 etc.)

- Carbon steel or carbon steel (material grade 1.1274, C100S, C75S)

- Spring steel (material grade 1.4310)

Non-ferrous metals are non-ferrous metals (without precious metals), we include:

- Copper (Cu) is resistant to corrosion, has good electrical conductivity, can be hot and cold formed. Type. Material grades: CW004A, CW008A, CW024A

- Copper, nickel, cobalt alloys (refractory)

- Bronze (hard, wear and corrosion resistant non-ferrous alloy, CW452K)

- Brass (good spring properties, cold formable. CW508L, CW612N)

- Nickel (Ni) or MU metal (ferromagnetic and particularly corrosion-resistant)

- Copper-Nickel

- Ceramic (Si3N4, particularly resilient, temperature-stable and thermal shock-resistant)

- Precious metals

- Numerous steel alloys

- Carbides, PCD diamond

- Pre-punched tapes with press-in zone

- Tantalum

- Hilumin

Contact-free and with the best beam quality, we cut a wide range of materials for you in laser fine cutting, most of which we have in stock:

- Non-ferrous and precious metals

- Stainless steels

- Various blasting alloys

- Nickel and cobalt alloys

- Carbides, PCD diamond

- Ceramics

- Pre-punched tapes with press-in zone

- Light metals

- Aluminum

- Copper alloys

- Titanium

- Tantalum

- Hilumin

Whether we also have your desired material currently in stock? Just ask.

Laser cutting: That speaks for the technology

The flexible and wear-free laser tool offers numerous advantages compared to other cutting and separating processes:

- Tool production: We create your sample or parts directly with the laser

- Wear and maintenance-free technology

- Low heat exposure and therefore hardly any warping (Heat Affected Zone, HAZ for short)

- No burr formation and therefore little to no reworking

- The laser beam achieves narrow kerfs of 0.025 to 0.08 mm

- Laser is ideal for precise, filigree structures and bevel cuts

- We use our CAD/CAM system to change the dimensions of the blanks as required

- Cutting contours can be adjusted quickly and flexibly

- The laser processes a wide range of materials and laser parts

- Material thicknesses up to 0.01 mm can be cut cleanly

A good choice: Precise laser parts delivered reliably.

A closer look at laser cutting

Laser source: There are different types of laser sources for cutting

such as CO 2 lasers and fiber lasers. Each of them has specific properties,

which are suitable for different applications such as metal processing.

Beam guidance: The laser beam is guided to the cutting head of the laser cutting device by means of mirrors or fiber cables

.

Focus: The laser beam is bundled by a lens in the cutting head,

to concentrate the energy on a very small point.

Melting: The focused laser beam heats the material to such an extent that it melts or vaporizes.

Laser head: During cutting, the laser head moves over the material (or the material under the laser head) so that the laser beam cuts the desired shape or geometry.