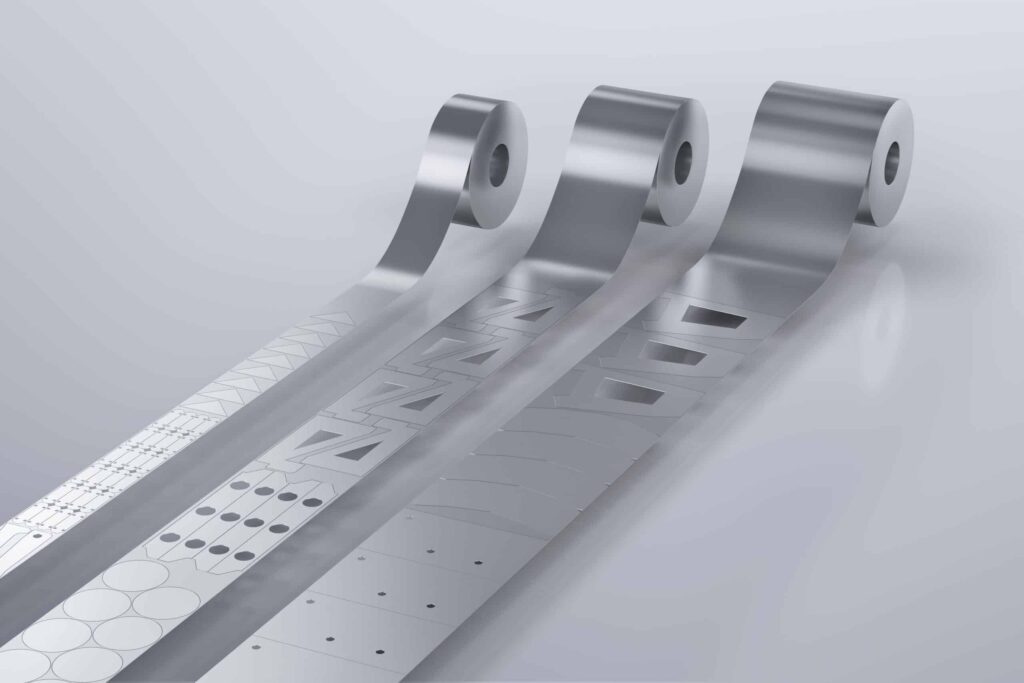

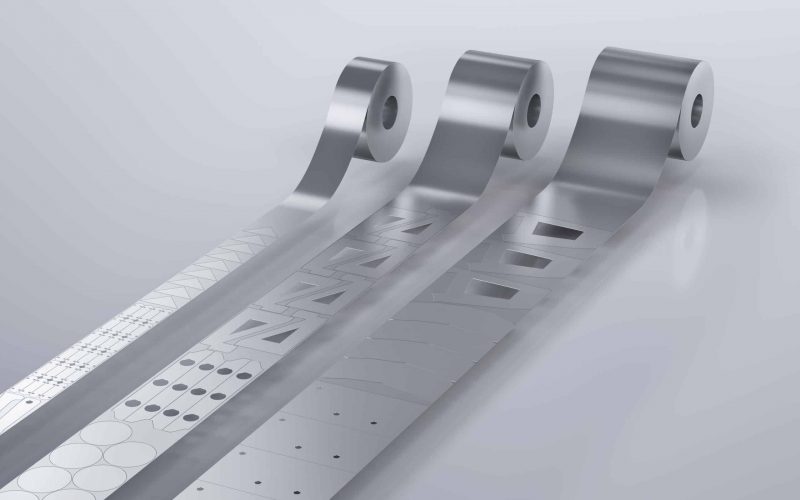

Soldering foil - Precise cutting & bending

Your silver solder and solder foil cut precisely & economically with laser or micro water jet

Bending and cutting of prototypes & series

Specialist for cutting silver solder and solder foil from 0.05 mm - 5.0 mm

HAILTEC is your specialist for the production of precision silver solderand solder foil components. With advanced laser fineblanking technologies, extensive experience and controlled manufacturing processes, we meet your specific needs. As an established premium supplier for various OEMs in medical technology, the automotive industry, mechanical engineering and other sectors, we use the latest ERP and DMS systems to ensure seamless traceability at every stage of production. For you, this means top quality.

Benefit from HAILTEC's precise and economical technologies for your parts made from solder foil / solder film

Components made from solder foil, fast & economical

Precise cutting & bending of solder foil at HAILTEC

| Precision is measurable: | Cutting solder foil |

|---|---|

| +/- 0.01 mm Contour accuracy* | |

| 0.05 mm - 5.00 mm cuttable material thicknesses in solder foil | |

| from 0.025 mm web widths* | |

| from 0.03 mm laser kerf* | |

| max. 800 x 500 mm Dimensions component | |

| *the mentioned values depend on material, thickness and geometry |

4 Cutting technologies in-house

Tell us your specifications (material, sheet thickness, technical requirements) and we guarantee you the most efficient solution - precise and economical. HAILTEC integrates four advanced cutting technologies under one roof: laser precision cutting, ultrashort pulse laser micro cutting, micro water jet cutting and punching technology.

Regardless of your specific requirements, we are a reliable partner and produce your components on machines from TRUMPF and DMG MORI. When selecting the optimum cutting technology, we take various factors into account, including your quality and material requirements, current capacity utilization and the issue of cost efficiency.

Is your demand skyrocketing? Use our automated systems for quantities of up to 500,000 units

Why implement challenging projects with HAILTEC?

Quality of components made from solder foil / solder film

At HAILTEC, the highest quality is at the heart of our production, especially in the manufacture of high-quality components made from solder foil and brazing foil. We rely on advanced technologies such as laser cutting and micro water jet cutting to ensure precise cuts. In addition, HAILTEC has state-of-the-art CNC swivel bending machines and offers the possibility to develop special tools and fixtures according to customer requirements. Our many years of expertise and extensive industry experience underline our commitment to quality and reliability at every stage of production. Trust HAILTEC to realize your most challenging projects.

Cutting solder foil:

Which solder foil alloys are suitable for precision cutting at HAILTEC?

There are various solder foil alloys on the market, which are selected depending on the area of application and the required properties of the solder joint. The best-known alloys include

Tin-lead (Sn-Pb) alloys: These are traditionally the most commonly used soldering materials, especially in electronics production. They offer good wettability and a low melting temperature. However, due to health and environmental concerns, the use of lead is increasingly being restricted.

Lead-free alloys: Lead-free alloys have been developed in response to the limitations of lead. Common compositions include tin-silver-copper (Sn-Ag-Cu, SAC), tin-copper (Sn-Cu) and tin-silver (Sn-Ag). These alloys have higher melting points than traditional tin-lead alloys, but are more environmentally friendly.

Silver-containing solder foils (Ag-based alloys): Silver-based alloys are often used for applications where high conductivity and a strong bond are required, such as in the medical and aerospace industries. They offer excellent wettability and mechanical strength.

Gold-tin (Au-Sn) alloys: These alloys offer very high reliability and excellent thermal and electrical properties. They are used, for example, in the semiconductor industry and for military connections.

Copper-tin (Cu-Sn) alloys: These alloys are often used for brazing, especially when joining copper parts. They offer high strength and corrosion resistance.

Tin-zinc (Sn-Zn) alloys: Sn-Zn alloys are an alternative for applications that require a low melting temperature but must be lead-free. They are particularly suitable for joining aluminum parts.

Indium-containing alloys: Indium-based alloys are used for special applications where a low melting temperature, good wettability and low outgassing are required, e.g. in vacuum technology and in the manufacture of LCD screens.

You can also use our machining processes as a full service

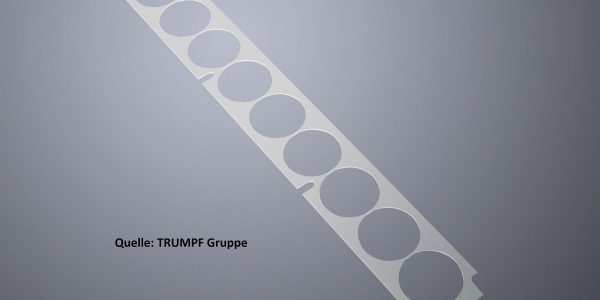

Which solder foil geometry can we produce for you?

Other services that might also interest you

Precise parts made from solder foil:

Laser-cut solder foil

- oxide-free cut edges, almost burr-free

- precise and economical

- Very low thermal input and distortion

Precise precision mechanical components

- smallest web widths possible

- Ideal for all common solder foil alloys

- Cutting tolerance up to +/- 20 µm

Why HAILTEC is the right partner for your industry

Looking for parts made from solder foil? HAILTEC GmbH specializes in the laser cutting and bending of solder foil, copper, aluminium, brass, stainless steel and many other metals and non-ferrous metals. We have been producing complex laser parts for the automotive industry, medical technology, mechanical engineering and many other sectors for many years. We therefore carry out our work according to uniform processes and clear standards. This ensures the consistent quality of our laser parts and comprehensive traceability of each individual production step.

With excellent beam quality and extremely small spot diameters, as a supplier

we fulfill your desire for maximum precision in laser cutting of solder foil. For applications in the following industries, among others:

- Tool and mould making

- Aerospace

- Measurement and control technology

- Watch industry

- Model making

- Embossing and punching technology

- Medical technology

- Automotive

- Mechanical Engineering

- E-mobility

- Electrical industry

- Micro / precision engineering

General information on solder foil

Solder foil is a thin material consisting of solder that is used specifically for joining metal parts by soldering. It enables precise and clean application of the solder, which is particularly advantageous for delicate or precision-critical manufacturing processes.

What applications is solder foil used for?

Solder foils are used in a wide range of industries, including electronics manufacturing, medical technology, automotive and mechanical engineering. They are particularly suitable for applications where uniform solder distribution and precise control of the solder quantity are required.

What are the advantages of solder foil over conventional solder?

Solder foils offer a number of benefits, including more precise control of solder quantity, more even distribution of solder, a reduction in soldering defects and an improvement in joint quality. They also enable clean and efficient production, especially for complex components.

Are there different types of soldering foils?

Yes, there are different types of soldering foils, which differ in their composition and melting points. Choosing the right solder foil depends on the materials of the parts to be joined and the specific requirements of the manufacturing process.

How is solder foil used?

Solder foil is placed between the metal parts to be joined and melted by heating. The liquid solder spreads evenly between the surfaces to be joined and forms a solid metallic bond after cooling.

Can solder foil be used for all metals?

Solder foil can be used for most metals, however it is important to select the correct type of solder foil for the specific metals and alloys to be joined. The compatibility and melting point of the solder foil must be matched to the materials of the components.