Copper laser cutting

Your copper sheets and copper foils precisely & economically laser cut

Laser cutting of copper for prototypes and series production

Specialist for laser cutting of copper & copper foils from 0.05 mm - 5.0 mm

HAILTEC stands for precision manufacturing of filigree components made of copper sheet and copper foils. Our modern and high-precision laser fineblanking machines, decades of experience as well as controllable processes enable us to meet your requirements to the full extent.

As a long-standing A-supplier of various OEMs from the medical technology, automotive, mechanical engineering and other industries, we ensure error-free batch traceability of each individual production step with state-of-the-art ERP and DMS systems.

Benefit from the precise and economical cutting technology of laser cutting for your parts made of copper

Precise copper blanks, fast & economical

Copper laser cutting with contour accuracy +/-0.01 mm

| Precision is measurable: | Copper laser cutting |

|---|---|

| +/- 0.01 mm Contour accuracy* | |

| 0.05 mm - 5.00 mm cuttable material thicknesses in copper | |

| from 0.025 mm web widths* | |

| from 0.03 mm laser kerf* | |

| max. 800 x 500 mm Dimensions component | |

| *the mentioned values depend on material, thickness and geometry |

4 Cutting technologies in-house

You tell us your ideas about material, sheet thickness and requirements, then we always deliver the most economical solution - high-precision and high-quality. To achieve this, we at HAILTEC combine four cutting technologies under one roof: laser fine cutting, ultrashort pulse laser micro cutting, micro water jet cutting and punching technology. No matter what your parameters are: We are your supplier and contact on machines from Trumpf and DMG MORI. There are several issues that must be considered when choosing the appropriate cutting technology. These include: What are your quality and material requirements? What is the prevailing workload? And what do you need to carry out production economically?

Your demand is skyrocketing? Use our automated laser systems for quantities up to 500,000 pieces

What characterizes laser cutting of copper at HAILTEC?

Quality of cuttings of copper foils and sheets

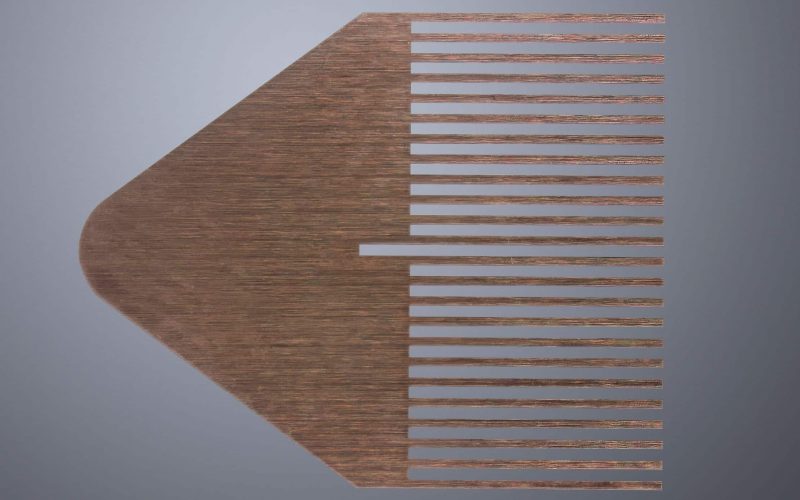

For precise laser cutting of highly reflective materials such as copper, we use QCW pulsed fiber lasers and Nd:YAG laser systems from DMG MORI and Trumpf. These laser sources introduce very little energy into the material/part. Little heat means little distortion and allows for high filigree cuts.

We use fine cutting laser systems and modern beam sources to achieve the finest cuts with a gap width of 0.03 mm or less. Tolerances are in the range of +/- 0.01 mm depending on the sheet thickness

Laser cutting of copper

Which copper alloys are suitable for precision laser cutting?

There are copper sheets in various alloys with different strengths and material properties. In this overview you will find the copper alloys we process most frequently. We have many of them permanently in stock, of course with material test certificates. We can also procure special alloys on request or you can provide us with the material.

Copper sheet CW008A (Cu-OF - 2.0040)

Cu-OF material is made of high purity and oxygen free copper (99.99% Cu minimum content). It is a very ductile copper sheet and is also suitable for brazing and welding. However, the machinability of the material is considered moderate to difficult.

Copper sheet CW024A (Cu-DHP - 2.0090)

Copper sheet CW004A (Cu-ETP - 2.0065)

The alloy CW004A - Cu-ETP has a very high conductivity for heat and electricity and is easily formable (hot and cold). It is also moderately to difficult to machine. Fields of application are electrical engineering, electronics, mechanical engineering and apparatus engineering.

Use our post-processing // surface finish for your laser parts made of copper

Which copper geometry can we precisely cut for you?

Other services that might also interest you

Precision copper laser cut parts are ideal for products such as:

Laser cut copper foil

- oxide-free cut edges, almost burr-free

- precise and economical

- Very low thermal input and distortion

Precise precision mechanical components

- smallest web widths possible

- ideal for copper and copper alloys

- Cutting tolerance up to +/- 10 µm

Why HAILTEC is the right partner for your industry

Laser cutting copper wanted? HAILTEC GmbH is a company specializing in laser cutting of copper, aluminum, brass, stainless steel and many other metals and non-ferrous metals.We have been producing complex laser parts for the automotive industry, medical technology, mechanical engineering and many other sectors for many years. Therefore, we carry out our work according to uniform processes and clear standards to ensure consistent quality of our laser parts and comprehensive traceability of each copper sheet production step.

With excellent beam quality and extremely small spot diameters, we fulfill your desire for maximum precision in laser cutting of copper as a supplier

. Among others for applications in the following industries:

- Tool and mould making

- Aerospace

- Measurement and control technology

- Watch industry

- Model making

- Embossing and punching technology

- Medical technology

- Automotive

- Mechanical Engineering

- E-mobility

- Electrical industry

- Micro / precision engineering

General information about copper

Most metals are oxidized or contain sulfur. They are called oxides or sulfites. Copper, however, is one of the few exceptions and is chemically one of the pure metals. The material has several advantageous attributes. Uniquely, copper is an excellent conductor of heat and electricity. In addition, raw copper is suitable for making alloys with other chemical substances. Zinc and tin are two different materials that can be processed differently.

- Copper is a metal that occurs in nature

- It is a red metal and has good conductivity

- It is an important metal for the industry and is used in many areas

- Copper is also used in medicine

Our offer is directed only to tradesmen from industry, engineering or crafts. We make individual copper cuts from the very first workpiece, and find the right solution for projects of any size. Copper is one of the oldest known materials and nowadays it has a very important role in many different industries. The reddish metal has a soft consistency and is mainly used in electrical and communication engineering. But copper is also in great demand for interior design or as piping.

The reason why copper is so sought after is mainly due to its excellent thermal conductivity and its very good electrical conductivity. In addition, it is a material that is uncomplicated to maintain. Although it is relatively easy to machine, copper is quite expensive compared to other metals. Therefore, it is particularly important to keep waste as low as possible when laser cutting.

Can copper be laser cut?

Copper belongs to the non-ferrous metals and is particularly difficult to process due to its highly shiny surface.

In particular, CO² lasers are not suitable for laser cutting of non-ferrous metals, gold and copper, as they conduct and strongly reflect heat.

Nevertheless, copper is ideal for laser cutting, but with pulsed fiber laser. The semi-precious metal has good electrical conductivity and good thermal conductivity.

Laser cutting of copper is a method that is always used when precise and reliable results are required in the processing of copper sheet - for example in medical technology, the automotive and electrical industries, or in vehicle and machine construction. It is a fast and cost-effective process that is suitable for cutting steel sheet as well as non-ferrous metals such as aluminum, brass or copper.

Why copper sheets and copper foil are challenging to process

Copper is very demanding when it comes to cutting it with laser beams. This requires special expertise and modern laser machines. The semi-precious metal is very good for reflecting light, for this reason it is extremely difficult to cut copper sheets with an ordinary CO2 laser. The very good thermal conductivity, similar to that of aluminum, distributes the heat evenly throughout the workpiece as soon as the laser beam touches it.

Since the melting point of copper is very high, an increased energy input by oxygen is required. This makes it possible to achieve a narrower cutting gap, which must nevertheless be wide enough to allow the cutting gas to be blown in. For cutting thin sheets of copper up to 3 mm thick, a pulsed fiber laser is particularly well suited. Fiber lasers are not quite as fast as a continuously emitting laser, but operate at low to medium power.

This results in the best quality and highest precision. The thermal load on the sheets is very low. A cutting gas, e.g. oxygen, nitrogen or argon, is used for cutting. It blows the melt that is produced during cutting out of the kerf and thus prevents the formation of scale. This results in almost burr-free cut edges.

What's the problem with reflective materials like copper sheet and copper foil?

Some metals have the property of acting almost perfectly as mirrors for laser light. This can mean that the high-energy laser beam is reflected in all directions, posing risks and problems for people and materials in the vicinity (especially with open laser machines).

The following materials are highly reflective and must therefore be handled and processed with extreme care: Silver, copper and gold.

The laser light can also be reflected and return to the laser source. This can cause irreparable or very expensive damage to the optics or the laser source itself. At HAILTEC, we have years of experience in laser processing of copper, so this challenge is not a problem for us.

How can HAILTEC laser cut these mirror metals like copper?

In practice, there are many tricks to reduce the mirror effect of materials. Most objects give off the highest mirror effect when they are in solid form.

Once copper is melted, the light it reflects back is reduced to about 90% depending on the temperature of the material. Aluminum reflects about 95% of the light when in solid form and about 70% when in liquid form.

As we can see, the first cut into the solid metal is the most problematic. On average, people have tried the various options to see if they work, from clearly emphasizing the path the laser takes to coating the top layer of metal. These methods work in different ways, but they all still pose a potential risk to the environment and the laser source. In practice, there is often not much choice and the risk is naturally present.

In principle, the damage caused by reflection is never compensated 100 percent. Therefore, it is a "calculated risk" where a balance between risk and outcome must be established.

Which is better copper sheet laser cutting or waterjet cutting?

The choice of cutting technology for a particular workpiece should be made dependent on its material properties as well as the requirements placed on it. Micro waterjet cutting is usually the alternative when weaknesses in laser cutting technology become apparent, e.g. no heat input is allowed.