Laser cutting medical technology

Your ISO 13485 certified contract manufacturer for precision cutting of meshes, bone plates and much more....

Laser cutting medical technology: safe, traceable, on schedule

Laser-cut implants made of titanium or nitinol: For you, we combine many years of experience in the production of implants with broad expertise in laser cutting medical technology. As an ISO 13485-certified contract manufacturer , we realize the finest contours with low tolerances quickly and accurately. Use our high technology for the production of your implants and medical components.

When do you relieve your production - and grow faster and more economically thanks to outsourcing to HAILTEC?

Use HAILTEC as an extended workbench to react to increased demand at short notice

Why choose HAILTEC as your supplier?

HAILTEC: Your contract manufacturer for laser cutting medical technology

We develop your workpieces, instruments, implants and other medical technology products together with you. We support you in the technological development processes from prototype to series production. We manufacture your product ISO 13485 compliant with:

- Laser cutting

- Precision bending

- Microbeams

- Surface treatment,

- Black Marking, UDI Labeling

- Cleaning

- Packaging, also possible in the clean room from 2024 onwards

.......complete and in the highest quality. With our services laser cutting, ultra-short pulse laser machining, CNC turning and milling, design, micro waterjet cutting and UDI compliant laser marking, we offer you all technologies in the field of precision machining.

This extremely process-safe technology of laser cutting medical technology allows us to process a wide variety of materials without damaging the surface. The resulting cut is minimally larger than the focused and pulsed laser beam itself - approximately 0.02 mm. In addition, our automated laser cutting equipment has extremely high accuracy and is ISO 13485 tested and validated by us on a regular basis.

Are you a medical device manufacturer looking for an ISO 13485 certified contract manufacturer for laser cutting medical technology?

This is the range of implant cutting services offered by HAILTEC

The ideal cutting process for every requirement

| Sheet thickness | Cutting method | Cutting gap | Tolerance |

|---|---|---|---|

| 0.01 - 0.5 mm | Ultra-short pulse micro cutting | approx. 0.015 mm | +/- 0.002 mm* |

| 0.05 to 3 mm | Laser fine cutting | 0.025 - 0.1 mm | +/- 0.010 mm* |

| 0.1-10 mm | Micro waterjet cutting | 0.3 - 0.5 mm | +/- 0.02 mm* |

| max. 2.5 mm | Punching technology | - | +/- 0,05 mm* |

*The tolerances mentioned in the table depend on the material.

What added value does implant cutting at HAILTEC offer?

Implant cutting at HAILTEC

As a development partner with a broad mix of processes and medical engineering experience, we realize your project agilely and precisely. Benefit from the combination of technological advantage and high-end measurement technology for your medical products.

Why choose HAILTEC as your supplier?

Laser cutting medical technology: Your expert for high-precision implant cuts

We manufacture laser-cut implants, implant systems and implant components according to your specifications. They are used in many parts of the human body, including the jaw and skull, hand or foot. Application and product examples Laser cutting medical technology:

- Mandibular fracture, mandibular reconstruction, covering bone defects (with titanium mesh at the cranial dome or in the orbital area), correcting joints.

- Plating systems for skulls and jaws

- Components for craniomaxillofacial osteosynthesis

- Titanium osteosynthesis implants

- Various implants in plate form such as chin plates, bone plates, hole plates or jaw angle plates

Material variety for your implants

Depending on your specifications, we process a variety of materials such as Nitinol as well as titanium and titanium mesh in different grades. For short distances, we stock a large selection of medical stainless steels. A little material science:

Titanium

The material titanium (Ti) is very corrosion-resistant, has a ductility that is important for the adaptation of the implant to the bone and is biocompatible. Depending on the expected load, we mix alloy additives such as aluminium or vanadium into the material to increase the strength of the implant.

Titanium or titanium meshes are used in various plate thicknesses and grades. Common grades are:

- Grade 2: Is a very popular titanium variant. With 99.25 % titanium content, it is particularly pure, bends well, has moderate strength and is therefore suitable for procedures with low mechanical stress in the bone.

- Grade 4: Still counts as pure titanium, but is significantly more durable thanks to added alloying substances.

- Grade 5: Withstands large forces, particularly suitable for screws.

Nitinol

The material Nitinol is an alloy of nickel-titanium and probably the best known form of a shape memory alloy. The elastic, biocompatible material is popular in medical technology. It is used, for example, for medical implants in trauma surgery, orthopedic surgery or coronary vascular surgery.

Product examples laser cutting medical technology

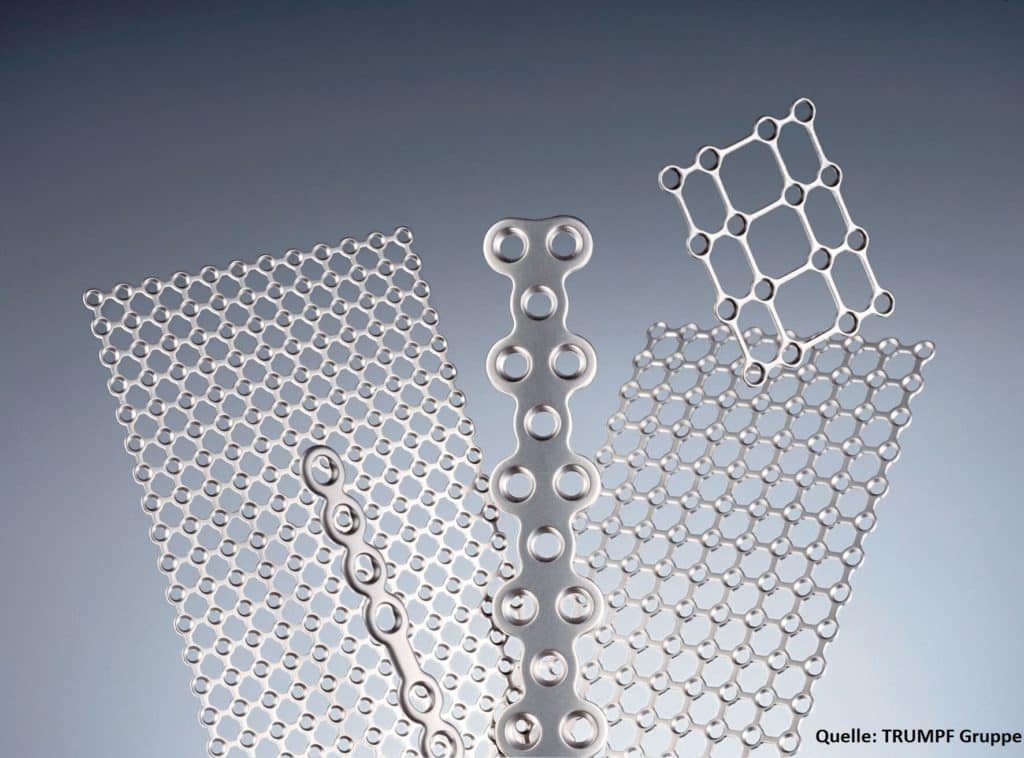

Titanium meshes and microplates

are mainly used in neurosurgery. In the field of osteosynthesis, it is important that the implants adapt to the human body shape / skull shape as best as possible.

- Variable geometric shapes

- Titanium mesh and microplates

- Round hole meshes and expansion meshes

Member of networks and associations

HAILTEC - Your certified partner

Frequently Asked Questions about ISO 13485 Laser Cutting Medical Technology

What are the advantages of laser cutting for medical technology at HAILTEC?

Laser cutting has numerous advantages in the field of medical technology. Through validated processes, we always ensure the same high quality standards for all our products. As a certified contract manufacturer according to ISO 13485, we are the ideal partner for your projects. Our state-of-the-art machinery enables us to manufacture the highest quality products for a wide range of applications. We are also always grateful to our specialized staff, who contribute with their expertise and experience to ensure that all our actions meet our quality and hygiene standards. We place great emphasis on meeting the highest standards in laser cutting to ensure customer satisfaction. Thus, we can provide you with flawless and high quality medical technology.

How is laser cutting controlled in medical technology?

Laser cutting in medical technology is extremely carefully controlled to ensure that every product that is manufactured meets the highest quality standards. This control takes the form of constant testing designed for precision and accuracy. First, the quality of the cutting material is checked to ensure that it is suitable for use in medical technology. Next, the quality of the laser cutting itself is checked. This involves checking the edge quality and surface accuracy to ensure that they meet the requirements. The accuracy of the cutting dimensions is also checked to ensure that the product meets specifications. To ensure the highest level of quality, the processes and the result of the laser processing are regularly checked. These tests are performed to ensure that the products being manufactured meet the highest quality standards. These tests include, but are not limited to, surface finish testing, laser processing accuracy verification, and dimensional measurement. All results are documented to ensure that each product meets requirements. A quality management system is also implemented on a regular basis to ensure that all processes are constantly monitored and improved.

What types of laser cutting are there in medical technology?

There are different types of laser cutting in medical technology. One of the most common types is thermal laser cutting, where a powerful laser beam is directed at the material to heat and melt it. This type of cutting is most suitable for finer details that need to be created very precisely and cleanly. Another type of laser cutting used in medical technology is ultrasound-based laser cutting, which uses an ultrasonic beam to cut the material. This process is most suitable for larger volume pieces that need to be cut quickly and efficiently. Another type of laser cutting used in medical technology is pulse laser cutting, in which a laser beam is directed at the material with very short pulses to cut it. This method is particularly suitable for creating very fast and precise cuts. All these types of laser cutting in medical technology have their own advantages and disadvantages and are suitable for different applications.

Why is HAILTEC ISO 13485 certified?

ISO 13485 is the international standard for quality management systems for the medical device industry. This standard specifies requirements for the organization, planning, control, performance and monitoring of the production, testing, packaging, storage and supply of medical devices. ISO 13485 is the basis for CE marking of medical devices.

The CE marking is a declaration of conformity issued by manufacturers and importers. It certifies that a product complies with the essential requirements of the EU directives. CE marking is mandatory for medical devices in the European Union.

The quality of our products and services is ensured by a sophisticated quality management system. Our employees are trained competently and responsibly and are required to complete regular further training measures. Through our continuous improvement process, we have successfully managed to optimize our processes and minimize sources of error. Comprehensive customer satisfaction: We constantly work on suggestions for improvement from our customers and implement them. Through regular exchange with our customers, we always succeed in exceeding the expectations placed on our company.

We constantly work on suggestions for improvement from our customers and implement them. Through regular exchange with our customers, we always succeed in exceeding the expectations placed on our company. Flexible solution concepts: The individually coordinated solution concepts for each individual order offer you the perfect combination of high-quality materials, state-of-the-art technologies as well as many years of experience in metalworking - all from a single source!

What surface treatments are used for implants and medical components?

Anodize:

- Anodizing is a process in which a metal or metal alloy is anodized in a chemical solution. This process is used primarily to protect or enhance the surface of a metal. Anodizing is a chemical process in which a layer is formed on the surface of a metal or metal alloy. This layer protects the metal from corrosion and wear. Anodizing can also be used to smooth or polish the surface of the metal.

Electropolishing:

- Electropolishing is an important process in medical technology. It ensures that surfaces are smooth and clean. This is important for instruments and devices to function properly. It also makes them look better. There are different types of electropolishing. Some are faster, others slower. In medical technology, fast polishing is often used to save time.

How does electropolishing work?

- A current is connected to a metal surface. The surface is immersed in a solution, often consisting of salt water and acid. The metal reacts with the solution and forms a layer of metal oxide. This layer is thicker than the original surface of the metal. So if you compare two metallic objects, you will see that one is smoother than the other. In medical technology, various metals are polished: Stainless steel, titanium and copper are just a few examples. Stainless steel polishing is the most common because it is so versatile - it can be used for just about anything!

Why do you need perfect surfaces?

- Smooth surfaces are hygienically cleaner than rougher surfaces. There are more cracks and crevices in rougher surfaces where bacteria can live (and these bacteria can spread disease). In addition, smooth surfaces have lower frictional forces - which means that instruments wear more slowly and can fail more slowly.

What is process validation with PQ, IQ and OQ?

Process validation is an essential part of quality assurance in the pharmaceutical industry. Validation involves the planning, execution and documentation of a series of tests to ensure that a process is reproducible and therefore reliable. Validation is usually divided into three phases: process qualification (PQ), installation qualification (IQ) and operational qualification (OQ).

Process qualification is a series of investigations aimed at optimizing the process so that it delivers the desired results. In this phase, the process is tested for reproducibility and robustness.

Installation qualification is a series of tests designed to ensure that equipment is properly installed and functioning properly.

Operational Qualification is a series of examinations that aim to

Why is titanium perfect for implants in medical technology?

Titanium is an extremely strong and durable metal, which makes it perfect for use in medical technology. Titanium implants are particularly durable and can withstand the body for a lifetime. In addition, titanium is biocompatible, which means that it does not cause allergic reactions and is also compatible with human tissue.